Decoding the Mysteries of Printed Electronics

With the relentless advancements in technology, the field of electronics is rapidly evolving. A relatively new and intriguing development in this domain is the concept of printed electronics. As the name suggests, printed electronics involve the use of printing methods to manufacture electronic devices and systems. This unique approach to electronics production has the potential to revolutionize the industry, offering several benefits over traditional manufacturing methods.

The Emergence of Printed Electronics

Printed electronics emerged as a result of the need for low-cost and flexible electronic devices. Traditional manufacturing methods often involve complex processes and expensive materials, which limit their affordability and adaptability. On the contrary, printed electronics utilize printing techniques similar to those used in the graphic arts industry, allowing for the production of flexible and cost-effective electronic devices.

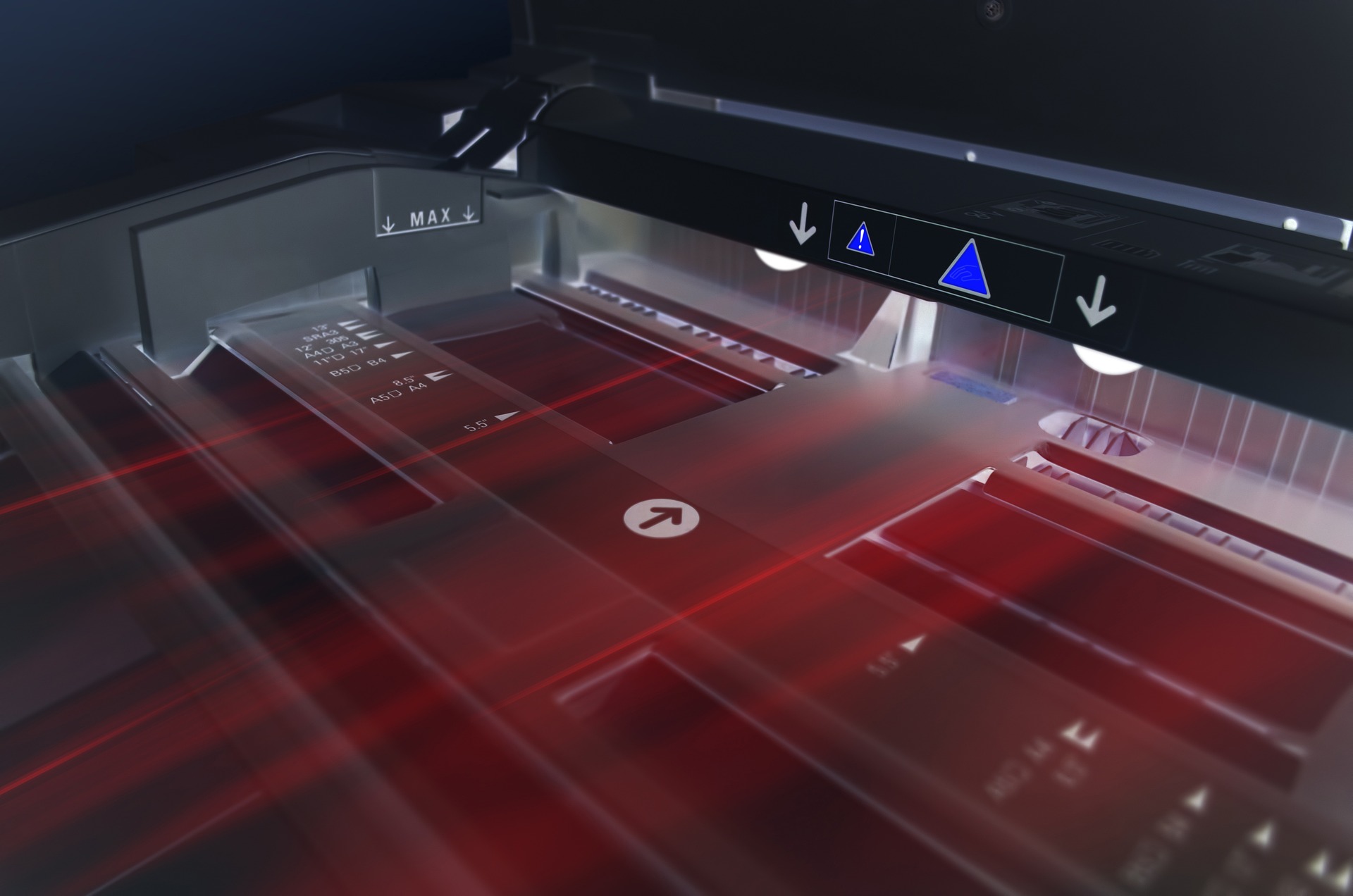

The Printing Process and Material Innovations

The printing process in printed electronics involves depositing electronic materials, such as conductive inks, onto substrates. These substrates can be flexible materials like plastic, paper, or fabric. The functional electronic components, such as transistors, sensors, and displays, are then printed onto these substrates using advanced printing techniques. The development of conductive inks, made from materials like silver, carbon, and organic polymers, has been a significant factor driving this technology.

Advantages of Printed Electronics

One of the major advantages of printed electronics is their flexibility. Unlike conventional electronics that are rigid and brittle, printed electronics can be bent, rolled, and folded without losing functionality. This makes them ideal for wearable devices, flexible displays, and electronic textiles. Additionally, printed electronics are lightweight and thin, which adds to their application potential.

The Potential Applications of Printed Electronics

Printed electronics have a myriad of potential applications across various sectors. In the healthcare industry, they can be used to develop wearable sensors for real-time monitoring of vital signs. In the retail sector, they can be incorporated into interactive packaging to enhance consumer engagement. Furthermore, they can be used in the production of solar cells, allowing for the creation of flexible and portable solar panels.

Challenges and the Road Ahead

Despite its numerous advantages, printed electronics also face several challenges. The main issue lies in the durability and performance of these devices, which currently fall short of their conventional counterparts. Moreover, developing efficient and reliable printing techniques remains a challenge. Nonetheless, with continued research and advancements, printed electronics hold the promise of a flexible and affordable future in the electronics industry.

- Rapid advancements in materials science are facilitating the development of better conductive inks for printed electronics.

- Printed electronics can significantly reduce the waste generated by traditional electronics manufacturing methods.

- Major tech companies like Samsung and Panasonic are investing heavily in research and development of printed electronics.

In conclusion, while printed electronics are still in their formative stage, their potential cannot be ignored. As research continues and technology advances, we can look forward to a future where electronics are not just flexible and affordable but also accessible to all. The era of printed electronics is just around the corner, promising to transform the electronics industry in unprecedented ways.