Discover the Experience of Working in Food Packing in Middlesbrough

Individuals residing in Middlesbrough and speak English have the opportunity to engage in food packing jobs. This role offers insight into the operational aspects of food packing environments, including working conditions, safety protocols, and day-to-day responsibilities. Understanding these elements can provide valuable context for those considering a career in this field.

Food packing constitutes a component of Middlesbrough’s industrial landscape as part of the broader food production industry in the region. This type of work typically involves preparing, packaging, and labeling food products to ensure they reach consumers in optimal condition. The food production sector generally maintains relative stability during economic fluctuations. This article provides general information about the nature of food packing work in Middlesbrough as an industrial sector, and does not represent specific employment listings or current job availability.

Understanding the Role of Food Packing in Middlesbrough

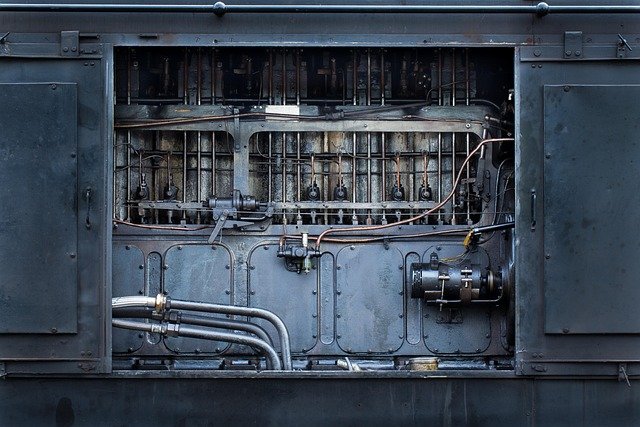

Food packing work in the Middlesbrough area typically involves several functions within the food production chain. Common responsibilities in this field generally include operating packaging machinery, manually packing products, conducting quality checks, maintaining cleanliness standards, and ensuring products meet specific weight and appearance requirements. The food packing industry in Middlesbrough encompasses various sectors, including ready meals, bakery products, confectionery, and fresh produce packaging. Each sector presents unique challenges and requirements, though all share core principles of food safety and quality control.

Food packing facilities typically operate on shift patterns, which may include early mornings, evenings, and sometimes weekend work. This schedule structure is common throughout the industry. The pace of work typically depends on production targets and seasonal demands, with busier periods often occurring around holidays and special events when food consumption increases throughout the country.

Exploring Work Conditions and Environment in Food Packing

The work environment in food packing facilities prioritizes cleanliness and safety. This industry typically operates in temperature-controlled settings, which may be chilled environments for certain food products. Personal protective equipment (PPE) is standard in the industry, including hairnets, gloves, and specialized clothing to maintain hygiene standards and protect both products and workers.

Physical aspects of food packing work include standing for extended periods, repetitive movements, and occasionally lifting moderate weights. Modern facilities increasingly incorporate ergonomic considerations to reduce physical strain, though the nature of the work remains relatively active. Noise levels vary depending on the machinery used, with some production lines operating at considerable volume levels requiring ear protection.

Social dynamics within food packing environments tend to be team-oriented, as production lines function most efficiently with good communication and cooperation. Many facilities employ diverse workforces, creating multicultural environments where cross-cultural communication skills are valuable. Break areas typically provide opportunities for social interaction among colleagues working similar shifts.

Skills and Requirements for a Successful Career in Food Packing

While entry-level food packing positions generally require no formal qualifications, certain skills and attributes contribute to success in this field. Attention to detail ranks among the valuable traits, as the work involves consistently identifying product defects and ensuring packaging meets quality standards. Physical stamina helps maintain productivity throughout shifts, while manual dexterity facilitates efficient handling of products and packaging materials.

Food hygiene knowledge, though often taught during training, is valuable for this industry. Understanding basic food safety principles demonstrates awareness of the industry’s priorities. Similarly, reliability and punctuality are important in production environments where absences can impact entire production lines.

Career progression within the food packing sector might include advancement to quality control positions, team leadership roles, or specialized machine operation after demonstrating competence and reliability. The industry sometimes offers training in food safety certification, machine operation, or supervisory skills.

Health and Safety Considerations in Food Packing

Food packing facilities adhere to strict health and safety regulations governed by both UK legislation and industry standards. The industry typically provides training on food safety protocols, including proper handling techniques, cross-contamination prevention, and allergen awareness. Personal hygiene requirements are stringent, with handwashing stations readily available and regular hygiene audits conducted.

Occupational health considerations include proper lifting techniques to prevent back injuries, rotation of tasks to reduce repetitive strain issues, and appropriate use of protective equipment. Many facilities implement regular health and safety briefings to maintain awareness and address emerging concerns. This industry typically requires health screenings and may involve periodic health checks to ensure food safety standards are maintained.

The COVID-19 pandemic prompted additional safety measures in many food packing facilities, including enhanced cleaning protocols, social distancing where possible, and improved ventilation systems. Many of these improvements have remained in place, contributing to generally healthier work environments throughout the industry.

Compensation and Benefits in Middlesbrough’s Food Packing Industry

Compensation structures in the food packing industry typically begin at or slightly above minimum wage for entry-level positions, with variations based on experience, shift patterns, and responsibilities. Night shifts and weekend work often command premium rates in this sector. Some operations offer productivity bonuses based on team or individual performance metrics.

Benefits packages vary considerably between employers, with larger operations typically offering more comprehensive packages. Common benefits in the industry include pension schemes, paid holiday entitlement, sick pay provisions, and employee discount programs for company products. Some employers provide subsidized canteen facilities, parking, and transportation assistance for shifts with difficult public transport connections.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Future Prospects and Industry Developments

The food packing industry continues to evolve, with technological advancements gradually changing workplace dynamics. Automation increasingly handles certain repetitive tasks, though human oversight remains essential for quality control and problem-solving. This technological integration creates new skill requirements for operating and maintaining sophisticated machinery.

Sustainability initiatives are becoming prominent within the industry, with many facilities transitioning to eco-friendly packaging materials and more efficient production methods. These changes sometimes require adaptation to new materials and processes, creating different skill requirements for those with environmental awareness and adaptability.

The post-Brexit landscape has introduced both challenges and opportunities for the food packing sector. While some facilities face supply chain adjustments and regulatory changes, others see increased focus on domestic food production. This evolving situation continues to shape the industry’s landscape.

This article provides general information about the food packing industry in Middlesbrough as an economic sector. It describes typical working conditions and industry standards rather than specific job openings or employment opportunities. Those interested in actual employment should consult current job listings and employment resources for available positions.