Discover Welding Training Opportunities Across United Kingdom of Great Britain and Northern Ireland (the)

Welding training offers individuals residing in United Kingdom of Great Britain and Northern Ireland (the) the chance to embark on a rewarding career with numerous pathways for growth. No prior experience or specialized education is necessary, making it accessible for anyone interested in entering the welding field. This program equips participants with essential skills and knowledge, preparing them for various roles in an industry that continues to expand.

Exploring the Benefits of Welding Training

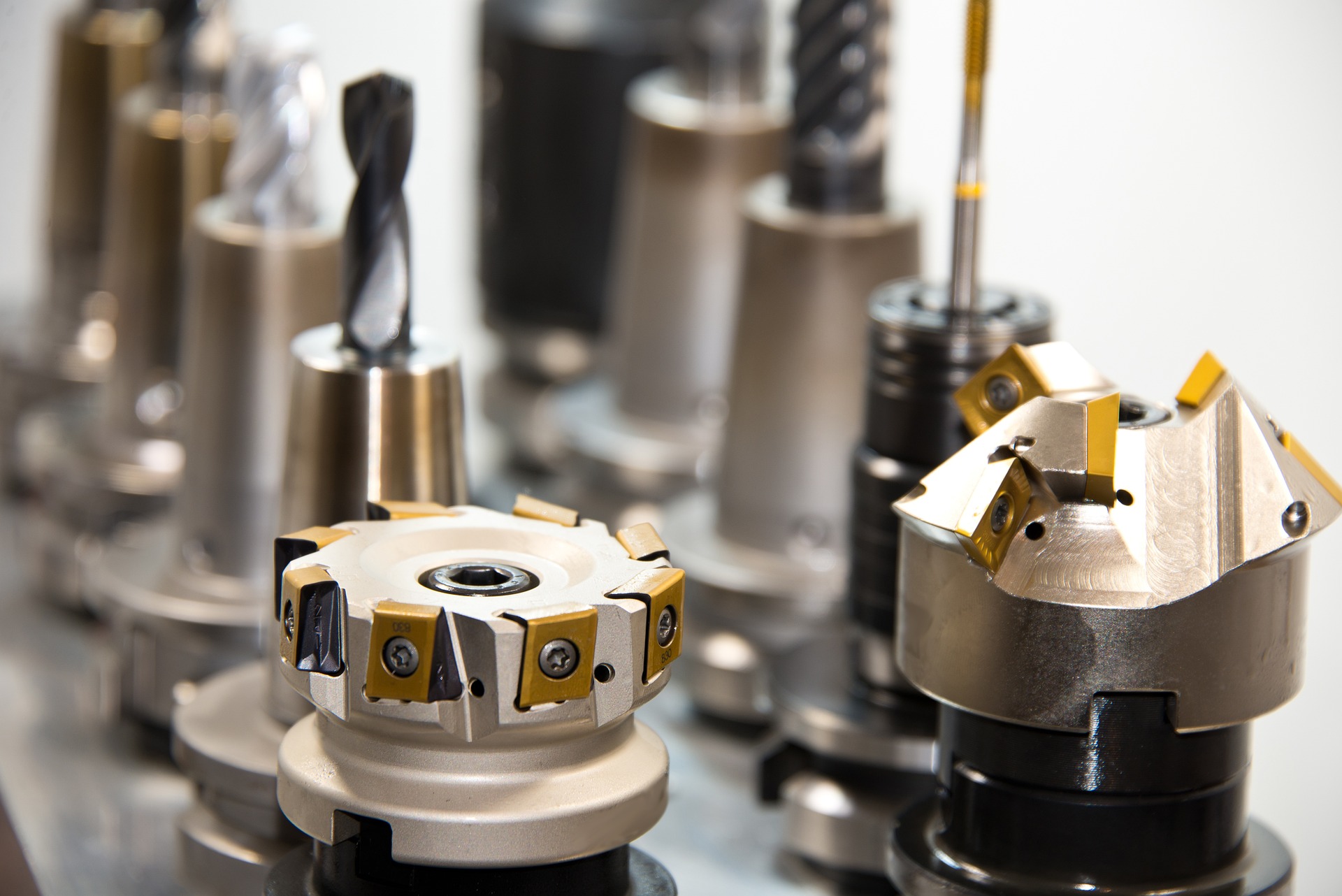

Welding training offers numerous advantages beyond simply learning a technical skill. Properly certified welders benefit from excellent employment prospects, with the skills shortage in this sector driving competitive wages across the UK. Training programs typically cover multiple welding processes including MIG, TIG, and arc welding, providing versatility that expands job opportunities. Additionally, many programs incorporate industry-recognised certifications such as those from the Welding Institute (TWI) or City & Guilds, which substantially enhance a welder’s credibility and employability in the marketplace.

The skills acquired through formal welding training are highly transferable across industries, from automotive manufacturing to offshore oil and gas, allowing professionals to pivot between sectors as market demands shift. Moreover, these programs often include training on advanced technologies such as robotic welding systems and computer-aided design, preparing students for the increasingly technological nature of modern welding environments.

The Pathway to a Rewarding Career in Welding

The journey toward becoming a qualified welder in the UK typically begins with foundational training through either further education colleges, private training providers, or apprenticeship programs. Entry-level courses such as Level 1 and 2 qualifications provide essential knowledge of welding fundamentals, materials science, and safety protocols. These introductory programs require minimal prerequisites, making them accessible to career changers and school leavers alike.

For those seeking more advanced qualifications, progression routes include Level 3 Diplomas in Fabrication and Welding Engineering Technology, which delve deeper into specialised techniques and theoretical understanding. Apprenticeships offer an alternative pathway, combining practical workplace experience with classroom learning over 2-4 years. These structured programs allow participants to earn while they learn, gaining valuable industry experience alongside formal qualifications.

Career advancement opportunities extend beyond initial training, with possibilities to specialise in underwater welding, high-integrity welding for nuclear applications, or moving into welding inspection and quality control. With sufficient experience, welders can pursue roles in supervision, project management, or even establish their own welding businesses.

What to Expect from Comprehensive Welding Training Programs

Quality welding training programs across the UK share certain core elements, beginning with thorough safety instruction. Students learn proper handling of equipment, appropriate personal protective equipment (PPE) usage, and workspace safety protocols. Theory components cover metallurgy basics, understanding how different materials respond to welding processes, and reading technical drawings and specifications.

Practical skill development forms the heart of these programs, with supervised workshop sessions where students practice various welding techniques on different materials and in different positions. As proficiency develops, tasks increase in complexity, culminating in projects that reflect real-world applications and challenges. Throughout training, assessment is ongoing, with regular feedback from instructors helping to refine technique and address any issues.

Training facilities typically feature industry-standard equipment, providing exposure to the tools and technology used in professional environments. Many programs incorporate simulated workplace scenarios to develop time management skills and work under pressure, preparing students for industrial environments. Additionally, some courses include site visits to manufacturing facilities or construction projects, giving students insight into various working environments and specialisations within the field.

Regional Training Opportunities Across the UK

Welding training availability varies across the UK regions, with each area offering unique specialisations reflecting local industry demands. In Scotland, institutions like Edinburgh College and North East Scotland College offer specialised programs supporting the offshore oil and gas sector, while Northern Ireland’s training often aligns with shipbuilding and aerospace industries through providers such as Northern Regional College.

Wales features strong connections to steel manufacturing and construction, with colleges like Coleg y Cymoedd providing relevant training programs. Throughout England, provision is extensive, with notable hubs in industrial areas like Sheffield, Manchester, and the Midlands through colleges such as The Sheffield College and Walsall College.

Urban areas typically offer greater choice of providers, while rural regions may have more specialised offerings focused on local industry needs. Many providers have developed flexible learning options, including evening courses and modular programs that accommodate working professionals seeking to upskill.

Welding Training Costs and Provider Comparison

Welding training costs vary significantly based on program level, duration, and provider type. Understanding the financial investment required helps prospective students make informed decisions about their training pathway.

| Training Provider | Program Type | Duration | Approximate Cost | Notable Features |

|---|---|---|---|---|

| The Welding Institute | Coded Welder Course | 2-8 weeks | £1,500-£3,500 | Internationally recognised certification |

| City & Guilds Centres | Level 2 Welding Skills | 1 year part-time | £1,000-£2,000 | Widely recognised qualification |

| ECITB Approved Centres | ECITB Welding Training | 4-12 weeks | £2,000-£4,000 | Industry-specific training for engineering construction |

| College-based Programs | Level 3 Diploma | 1-2 years | £2,500-£7,500 | Comprehensive theoretical and practical training |

| Private Training Providers | Short Intensive Courses | 1-4 weeks | £800-£1,500 | Focused skill development in specific techniques |

| Apprenticeship Programs | Welding Apprenticeship | 2-4 years | Funded/Paid | Earn while you learn with employer placement |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Funding options can significantly reduce these costs, with the Advanced Learner Loan available for eligible students on qualifying Level 3-6 courses. Additionally, apprenticeships are typically funded through employer and government contributions, with apprentices receiving a salary throughout their training. Various grants and bursaries may also be available through organisations like the Welding Institute or industry-specific bodies, particularly for underrepresented groups in the welding industry.

Future Prospects in the Welding Industry

The welding profession in the UK faces a promising future, with the skills gap creating steady demand for qualified professionals. Major infrastructure projects like HS2, nuclear power developments, and renewable energy installations continue to drive employment opportunities. Technological advancements in the industry, including automation and digital technologies, are reshaping the field, with modern welders increasingly needing digital literacy alongside traditional skills.

Environmental considerations are also influencing the industry, with growing emphasis on sustainable practices and reduced emissions in welding processes. This evolution creates opportunities for welders with up-to-date training and awareness of emerging technologies and methods. As the industry continues to develop, those with comprehensive training and a commitment to ongoing professional development will be best positioned to benefit from these changes and contribute to the UK’s industrial capacity.