Explore Industrial Manufacturing Job Opportunities in United Kingdom of Great Britain and Northern Ireland (the)

For individuals residing in United Kingdom of Great Britain and Northern Ireland (the) and interested in pursuing a career in industrial manufacturing, there are numerous opportunities available. Starting with specialized training programs can equip aspiring workers with the essential skills needed to thrive in this sector. Engaging in these programs can provide a solid foundation for a successful career in manufacturing.

Manufacturing Industry Qualifications Overview

The manufacturing sector recognizes different education and training levels. General qualifications include GCSEs for entry-level positions, NVQ certifications for technical roles, and engineering degrees for specialized positions. Digital literacy complements traditional technical skills, with knowledge of manufacturing software systems becoming increasingly relevant.

Professional certifications through organizations like the Institution of Engineering and Technology (IET) represent common development paths. Manufacturing environments typically value both practical experience and formal education. Educational requirements vary by role type and specialization area.

Professional Development Pathways

Manufacturing career development often includes formal education and practical training. Common education formats include apprenticeships, technical certifications, and degree programs. Training typically covers areas such as quality control, workplace safety, and specific manufacturing processes.

Professional advancement may involve specialized training in areas like Six Sigma methodology, lean manufacturing principles, or advanced manufacturing technologies. Educational institutions frequently develop industry-relevant programs. Skills development focuses on both traditional manufacturing practices and emerging technologies.

Industry Structure and Distribution

The manufacturing sector employs approximately 2.7 million people across the UK. Regional concentrations include automotive manufacturing in the Midlands, aerospace in the Northwest, and food production in Scotland. The industry structure continues evolving through technological advancement and automation integration.

Different regions maintain specialized manufacturing focuses. Aerospace manufacturing concentrates on advanced materials and precision engineering. Automotive manufacturing encompasses vehicle assembly and component production. Food and beverage manufacturing operates throughout various regions.

Manufacturing Compensation Structure

Manufacturing sector compensation varies by position, experience level, and location. The following ranges represent typical compensation structures rather than specific offerings:

| Role Category | Early Career Range | Advanced Range | Standard Benefits |

—|—|—|—

| Production Operations | £18,000 - £22,000 | £22,000 - £28,000 | Shift differentials, overtime |

| Technical Maintenance | £25,000 - £30,000 | £30,000 - £40,000 | Training programs |

| Engineering | £30,000 - £35,000 | £40,000 - £60,000 | Development opportunities |

| Production Management | £35,000 - £45,000 | £45,000 - £70,000 | Performance incentives |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

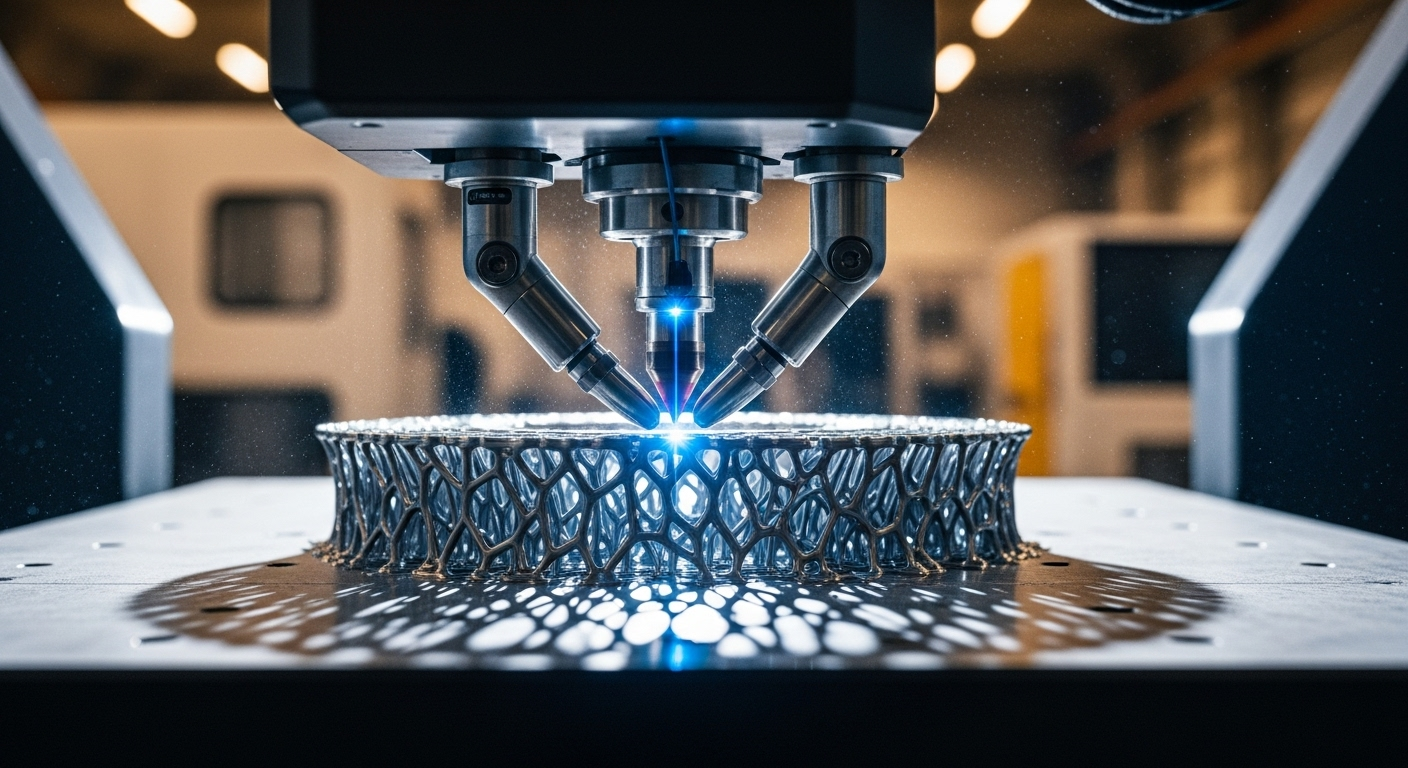

Current Industry Developments

Manufacturing continues evolving through Industry 4.0 technologies. Focus areas include sustainable manufacturing, automated systems, and advanced materials. These developments influence skill requirements across digital systems, data analytics, and process control.

Technology integration includes artificial intelligence, Internet of Things (IoT) devices, and robotics systems. Environmental initiatives affect manufacturing processes and methods. Modern facilities utilize data analysis and automated systems for production optimization.

The manufacturing sector maintains significance in the UK economy while adapting to technological changes. Combined traditional and digital expertise shapes current manufacturing practices. Industry investment continues in advanced technologies and sustainable methods.

Technical knowledge areas include predictive maintenance, quality control systems, and digital manufacturing processes. The sector balances traditional manufacturing practices with technological advancement. Understanding these aspects provides context for manufacturing career planning.

Manufacturing continues evolving through technological advancement and changing requirements. The sector maintains economic significance while adapting to new developments. Individuals interested in manufacturing careers should research current conditions in their target specialization and location.

This overview provides general manufacturing sector information rather than specific employment opportunities. Career development in manufacturing requires understanding both traditional practices and emerging technologies. The industry landscape continues changing through technological advancement and evolving requirements.

Those considering manufacturing careers should conduct thorough research into specific areas of interest. Local market conditions, educational requirements, and industry developments vary by region and specialization. Professional organizations and educational institutions provide additional resources for detailed information about manufacturing career paths.