Exploring Food Packing Work and Environments Across Charleroi.

Food packing has become an essential part of Charleroi’s logistics and food industry. This article explores how warehouse environments are typically organized, what daily routines look like, and which tasks are commonly performed in food packing facilities. Readers can also learn about hygiene standards, teamwork dynamics, and safety measures that define this type of work environment — without implying any specific job listings or recruitment offers.

The food packing industry in Charleroi operates as a cornerstone of the regional supply chain, connecting local food producers with distribution networks across Belgium and beyond. Workers in these facilities engage in systematic processes that transform raw ingredients and prepared foods into market-ready products through specialized packaging techniques.

Food Packing Systems in Charleroi’s Supply Chain

Food packing is an important part of Charleroi’s food supply and logistics system, supporting both local manufacturers and international food brands. The city’s strategic location within Belgium makes it an ideal hub for food processing and distribution operations. Facilities typically handle diverse product categories including frozen foods, fresh produce, processed meats, dairy products, and packaged goods destined for supermarkets and restaurants throughout the region.

Warehouse Operations Structure and Daily Tasks

Articles often describe how warehouse operations are structured and what typical daily tasks include in modern food packing environments. Workers typically begin shifts with safety briefings and equipment checks before moving to designated packing stations. Daily responsibilities include operating packaging machinery, quality inspection of products, labeling and coding packages, organizing inventory systems, and maintaining clean work areas according to food safety protocols.

The workflow generally follows a systematic approach where products move through various stations including preparation areas, packaging lines, quality control checkpoints, and final storage zones before distribution.

Safety Standards and Working Conditions

Hygiene and safety standards play a key role in maintaining proper working conditions within Charleroi’s food packing facilities. Workers must adhere to strict cleanliness protocols including regular hand washing, wearing protective clothing such as hairnets and gloves, and following temperature control procedures for different food categories.

Safety measures extend beyond personal hygiene to include proper lifting techniques, machinery operation protocols, and emergency procedures. Facilities maintain controlled environments with appropriate temperature and humidity levels to preserve food quality during packaging processes.

Coordination and Efficiency in Packing Processes

Teamwork and coordination help ensure efficiency in packing processes across different production lines. Workers collaborate in assembly-line formats where each person handles specific tasks such as filling containers, sealing packages, applying labels, or conducting quality checks. Communication between team members prevents bottlenecks and maintains consistent production flow.

Supervisors coordinate shift schedules, monitor production targets, and ensure compliance with food safety regulations while maintaining productivity standards that meet distribution deadlines.

Understanding Food Packing Environments

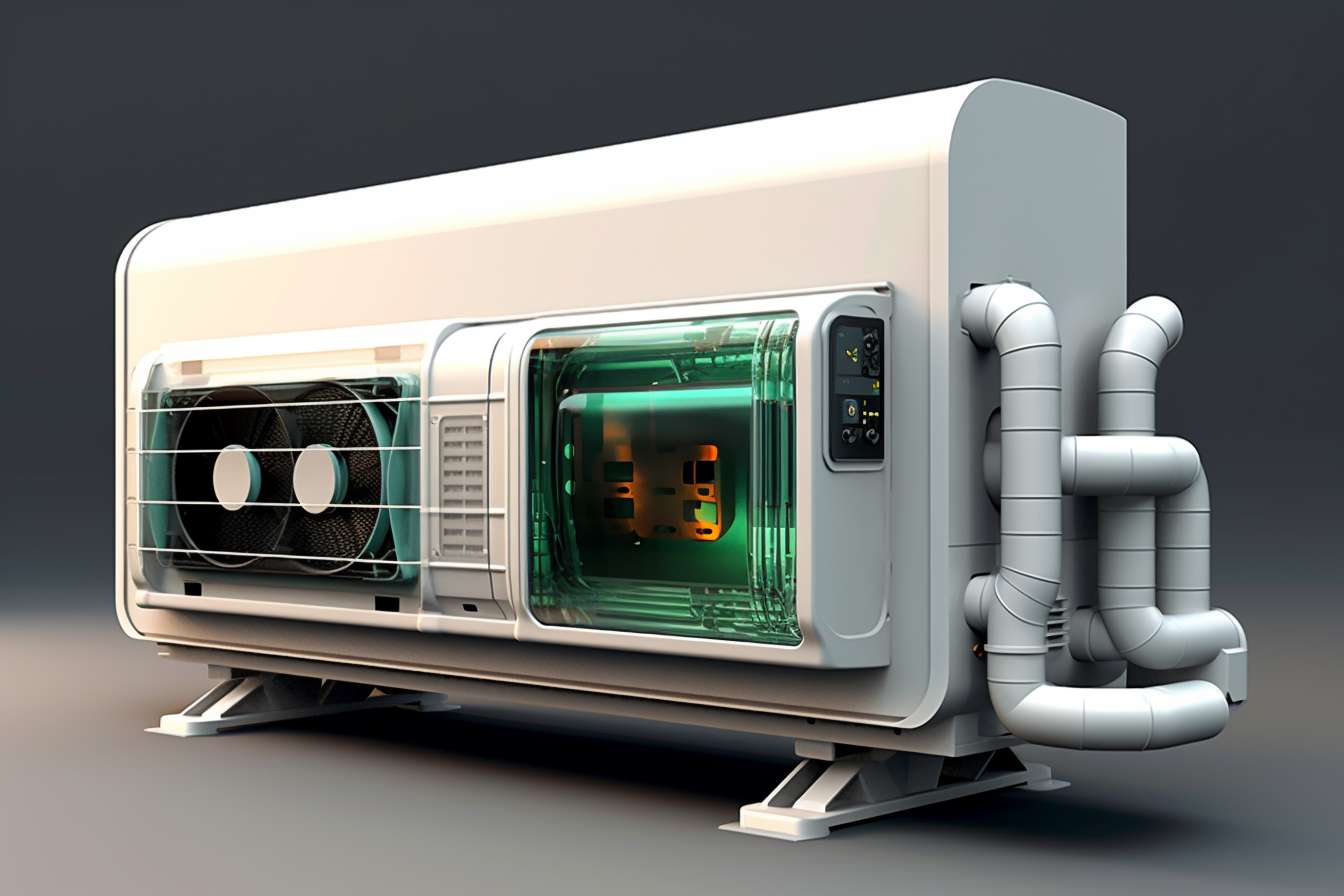

The article explores how food packing environments function without implying any job offers, focusing instead on the operational aspects that characterize these industrial settings. Modern facilities incorporate automated systems alongside manual processes, creating work environments that require both technical skills and physical coordination.

Environmental factors include controlled lighting for detailed inspection work, ventilation systems that maintain air quality, and ergonomic workstation designs that reduce physical strain during repetitive tasks. These facilities often operate multiple shifts to accommodate continuous production demands.

| Facility Type | Typical Products | Key Features |

|---|---|---|

| Frozen Food Processing | Ice cream, frozen vegetables, prepared meals | Temperature-controlled environments, specialized freezing equipment |

| Fresh Produce Packing | Fruits, vegetables, salads | Refrigerated storage, rapid processing systems |

| Processed Foods | Canned goods, packaged snacks, beverages | High-volume packaging lines, automated labeling systems |

| Dairy Processing | Milk products, cheese, yogurt | Sterile environments, cold chain maintenance |

Food packing work in Charleroi encompasses various skill levels and specializations, from entry-level packaging positions to technical roles involving machinery operation and quality control. The industry provides insights into modern food distribution systems while highlighting the importance of maintaining food safety standards throughout the packaging process.

These facilities contribute significantly to Charleroi’s industrial landscape, supporting both local employment and the broader food supply network that serves Belgian consumers and export markets.