Industrial Manufacturing Training Available for English Speakers in United Kingdom

Individuals residing in United Kingdom and proficient in English may consider participating in Industrial Manufacturing Training. This training program aims to equip participants with essential skills relevant to the industrial manufacturing sector. The curriculum is designed to enhance understanding of manufacturing processes, techniques, and safety protocols, ultimately facilitating entry into this field.

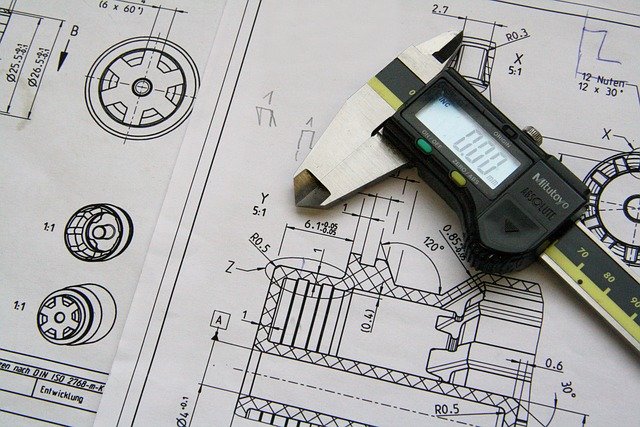

The industrial manufacturing sector remains a cornerstone of the United Kingdom’s economy, contributing significantly to employment opportunities and economic growth. As technology continues to transform manufacturing processes, there is an increasing demand for skilled professionals who can navigate the complexities of modern industrial environments. For English speakers in the UK, numerous training pathways exist that combine technical knowledge, practical skills, and industry-relevant qualifications. These programs are designed to equip individuals with the competencies required to thrive in this evolving sector, from entry-level positions to specialized technical roles.

Overview of Industrial Manufacturing Training in United Kingdom

Industrial manufacturing training in the UK encompasses a diverse range of programs tailored to different aspects of the manufacturing process. These include apprenticeships, vocational qualifications, higher education degrees, and specialized short courses. The training landscape is supported by a network of further education colleges, universities, private training providers, and employer-led initiatives. Many programs follow frameworks established by organizations such as the Engineering Council, the Manufacturing Technology Centre (MTC), and sector skills councils like Semta (Science, Engineering, Manufacturing Technologies Alliance).

Training typically covers fundamental manufacturing principles, specific technical skills, health and safety regulations, quality control procedures, and increasingly, digital manufacturing technologies. The UK government’s focus on developing advanced manufacturing capabilities has led to enhanced investment in training infrastructure, particularly in areas such as automation, robotics, and sustainable manufacturing practices. Regional manufacturing hubs in places like the Midlands, Yorkshire, and Scotland often feature specialized training facilities that reflect local industrial strengths.

Language Requirements for Training in Industrial Manufacturing

For English speakers, the language requirements for industrial manufacturing training in the UK are generally straightforward. Most training programs are conducted in English, making them accessible to native speakers and those proficient in the language. However, the technical nature of manufacturing training introduces specialized vocabulary and concepts that all learners must master. This includes terminology related to machinery, production processes, materials science, and engineering principles.

For non-native English speakers seeking training in the UK manufacturing sector, programs typically require evidence of English language proficiency. This often means achieving minimum scores on recognized tests such as IELTS (International English Language Testing System) or TOEFL (Test of English as a Foreign Language). The specific requirements vary between institutions, but generally, a score equivalent to CEFR (Common European Framework of Reference for Languages) level B2 or higher is expected for technical training programs.

Some training providers offer additional language support for technical terminology, recognizing that even fluent English speakers may need assistance with industry-specific language. This support can include specialized glossaries, supplementary language classes focused on technical vocabulary, or peer mentoring systems.

Pathways to a Career in Industrial Manufacturing

The UK offers multiple entry points for those pursuing careers in industrial manufacturing. Apprenticeships represent a traditional and increasingly popular route, combining workplace learning with classroom instruction. These programs, which typically last 2-4 years, allow participants to earn while they learn and often lead to recognized qualifications such as NVQs (National Vocational Qualifications) or HNCs (Higher National Certificates).

For those preferring an academic pathway, universities across the UK offer degrees in manufacturing engineering, production management, and related disciplines. These programs provide theoretical foundations and increasingly incorporate practical elements through industry placements and project work. Foundation degrees and HNDs (Higher National Diplomas) offer intermediate qualifications that balance academic study with practical skills development.

Continuing professional development plays a vital role in manufacturing careers, with numerous short courses and specialized certifications available for existing professionals. These include training in specific manufacturing technologies, management systems, or regulatory compliance. Professional bodies such as the Institution of Mechanical Engineers (IMechE) and the Institution of Engineering and Technology (IET) offer structured development frameworks and chartered status for manufacturing professionals.

Training Facilities and Resources Across the UK

The United Kingdom boasts an extensive network of training facilities dedicated to industrial manufacturing. These range from purpose-built training centers within further education colleges to advanced manufacturing research facilities that offer specialized training. Notable examples include the Advanced Manufacturing Training Centre in Coventry, the AMRC Training Centre in Sheffield, and the National Manufacturing Institute Scotland.

These facilities typically feature industry-standard equipment, allowing trainees to develop practical skills on the same machinery they will encounter in workplace settings. Many incorporate the latest technologies, including digital twins, virtual reality training simulations, and collaborative robots, preparing learners for the increasingly digital manufacturing environment.

Industry partnerships enhance these resources, with many major manufacturers maintaining their own training academies or collaborating with educational institutions. Companies such as Rolls-Royce, BAE Systems, and Siemens invest significantly in training infrastructure, often making these resources available to their supply chain partners and the wider manufacturing community.

Manufacturing Training Providers and Courses

| Provider | Course Types | Key Features |

|---|---|---|

| EEF Technology Centre | Apprenticeships, Short Courses | Industry-standard equipment, SME focus |

| Make UK | Technical Training, Management Courses | National coverage, employer-led content |

| AMRC Training Centre | Advanced Apprenticeships | High-tech facilities, aerospace specialization |

| National Manufacturing Institute Scotland | Professional Development | Research integration, future manufacturing focus |

| In-Comm Training | Apprenticeships, Adult Skills | Employer-led curriculum, progression pathways |

| Manufacturing Technology Centre | Digital Manufacturing, Automation | Leading-edge technology, industry partnerships |

Future Trends in Industrial Manufacturing Training

The landscape of industrial manufacturing training in the UK continues to evolve in response to technological advancements and changing industry needs. Digital skills have become increasingly central to training programs, reflecting the growth of Industry 4.0 technologies such as the Internet of Things (IoT), artificial intelligence, and data analytics in manufacturing environments. Training providers are incorporating these elements into their curricula, often through simulated smart factory environments and digital twin technologies.

Sustainability is emerging as another key focus area, with training programs increasingly covering sustainable manufacturing practices, circular economy principles, and carbon reduction strategies. This reflects both regulatory pressures and market demands for environmentally responsible manufacturing processes.

The delivery methods for manufacturing training are also transforming, with greater emphasis on blended learning approaches that combine online instruction with hands-on practice. Virtual and augmented reality technologies are being deployed to create immersive training experiences, particularly for high-risk or complex procedures where physical training might be impractical or dangerous.

As the UK manufacturing sector continues its technological transformation, training programs will likely place greater emphasis on adaptability and continuous learning, preparing participants not just for current manufacturing practices but for a career of ongoing development in this dynamic field.