Insights into Food Packing Jobs in Austria for English Speakers

Individuals residing in Austria and proficient in English may find insights into the food packing sector within warehouse environments. These roles involve handling various food items, ensuring proper packaging, and adhering to safety protocols. Understanding the working conditions, including the physical demands and collaborative aspects of the job, is essential for those considering this field.

Insights into Food Packing Jobs in Austria for English Speakers

Food packing work in Austria is often part of a larger system that connects food producers, distribution centers, and retailers. While tasks can look straightforward from the outside, the job typically involves accuracy, pace, and strict handling rules—especially where temperature control, allergens, or traceability are involved. For English-speaking workers, success usually depends on understanding the workflow and learning enough operational vocabulary to follow instructions safely and consistently.

Food packing in warehouse operations

Understanding the Role of Food Packing in Warehouse Operations starts with seeing packing as the final checkpoint before goods move to customers or stores. In many facilities, packing follows picking: items are selected from storage locations, verified, packed into the right packaging, labeled, and staged for dispatch. Accuracy matters because packing errors can trigger returns, spoilage, or compliance issues—particularly with products that have use-by dates, batch numbers, or storage requirements.

Food packing can include portioning (when permitted and trained), sealing, applying barcodes, adding inserts (such as allergen information), and completing documentation that supports traceability. Some sites use scanners and warehouse management systems to confirm each item; others rely on checklists and visual controls. You may also encounter workflows such as FIFO (first in, first out) rotation, where the packing station must ensure older stock ships first to reduce waste.

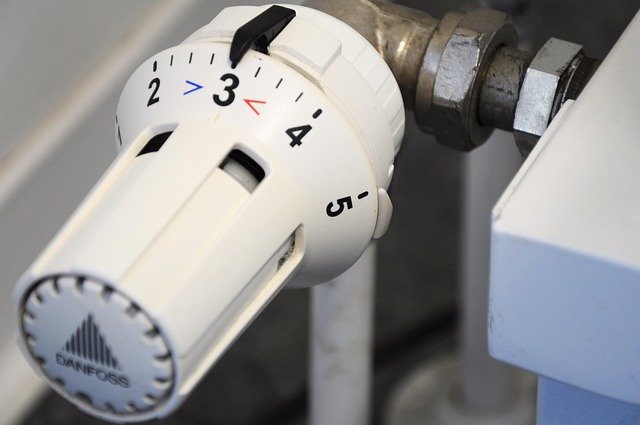

Operationally, packing stations are designed to keep throughput steady. That can mean standardized packing materials, clear work instructions, and defined quality checks—like verifying weight, seals, labels, or temperature readings. A practical way to think about the role is that packing protects product integrity and ensures the outbound shipment matches what was ordered, in the condition required.

Working in food packing environments in Austria

Key Considerations for Working in Food Packing Environments often center on hygiene, safety, and consistency. Many food packing areas follow strict cleanliness routines: handwashing procedures, restrictions on jewelry, hair covering, and rules about food contact surfaces. Even if you are not directly handling unpackaged food, you may need to follow zoning rules (for example, “clean” vs. “general” areas) to prevent contamination.

Temperature-controlled work is common. Austria has significant cold-chain logistics supporting dairy, meat, frozen goods, and ready-to-eat items. This can involve working in chilled rooms, handling insulated packaging, and minimizing door-open times to protect product temperature. In these settings, personal protective equipment may include thermal gloves or insulated clothing, and breaks may be scheduled to reduce strain.

Allergen control is another frequent requirement. Facilities may separate packing lines or enforce cleaning and changeover steps to reduce cross-contact risks (for example, between products containing nuts, milk, or gluten). Practical discipline—such as using the right containers, respecting color-coded tools, and following disposal rules—can be as important as speed.

Work organization can include shift patterns, performance targets, and team-based stations. It helps to be prepared for repetitive motions and standing work, as well as the need to maintain focus under time pressure. If you are new to warehouse settings, asking for clarification early—especially on safety rules like emergency exits, lifting guidance, and equipment traffic lanes—can prevent mistakes and improve confidence.

Language skills for English speakers

Language Skills and Their Value in Food Packing Roles is not only about conversation; it is about safety, compliance, and smooth handovers. In Austria, German is commonly used for signage, safety briefings, and written work instructions. English may be present in multinational teams or where systems, labels, or management communication use English terms, but it is not guaranteed across all facilities.

For English speakers, the most useful language goal is often “operational German”: understanding numbers, dates, common safety words, and task verbs used on the floor. Being able to confirm quantities, recognize product variants, and report issues (like damaged packaging, wrong label, or temperature concerns) reduces risk. Even limited German can be valuable when supervisors rotate, when instructions change mid-shift, or when emergency procedures are explained.

At the same time, English skills can be an asset in mixed teams, especially where onboarding materials, equipment manuals, or cross-site communication are partially in English. Clear communication habits matter in any language: repeating back instructions, using standard terms for locations and items, and documenting exceptions. If you are working in a team, agreeing on simple shared phrases for “stop,” “check,” “missing item,” or “label problem” can reduce errors and keep the workflow calm and predictable.

In practice, language needs also depend on the complexity of the operation. Manual packing with simple product lines may require less reading and system interaction than a site with scanning, batch tracking, and frequent changeovers. When assessing your fit, focus on whether you can reliably follow safety instructions, understand quality checkpoints, and communicate problems quickly.

A food packing role in Austria can be a structured way to participate in the supply chain, with clear routines and measurable standards. For English speakers, the key is aligning expectations with the realities of warehouse operations, hygiene-focused environments, and the language used in daily coordination. With a strong grasp of the workflow and an emphasis on safety and accuracy, the work becomes easier to navigate and more consistent from shift to shift.