Insights into the professional fields of cosmetic packaging in Düsseldorf

Individuals with good German skills and residence in Düsseldorf can gain insights into the world of cosmetic packaging. The role encompasses a wide range of tasks related to packaging cosmetic products and requires precision as well as knowledge of quality control. Experience with typical working conditions in the cosmetic packaging industry is advantageous.

The cosmetic packaging industry in Düsseldorf represents a vital component of Germany’s broader beauty and personal care manufacturing sector. This field combines technical precision with aesthetic considerations, requiring workers to maintain high standards while meeting production targets. The city’s industrial infrastructure and proximity to major European markets make it an attractive location for cosmetics manufacturers and packaging specialists.

Understanding the role of cosmetic packaging in Düsseldorf

Cosmetic packaging professionals in Düsseldorf engage in various activities that ensure products reach consumers in optimal condition. These roles typically involve operating specialized machinery, conducting quality inspections, and maintaining hygiene standards throughout the packaging process. Workers may handle different product categories including skincare items, makeup products, and personal care accessories. The packaging process requires attention to detail, as products must meet regulatory compliance standards and brand specifications. Many positions involve working with automated systems while also performing manual tasks such as labeling, sealing, and product arrangement. The industry demands consistency and precision, as packaging directly impacts product safety and consumer perception.

Working conditions in the cosmetics packaging industry

The working environment in Düsseldorf’s cosmetic packaging facilities typically features clean, temperature-controlled spaces designed to maintain product integrity. Most facilities operate multiple shifts to maximize production efficiency, offering flexibility for workers with different schedule preferences. Safety protocols are strictly enforced, with personal protective equipment provided and regular training sessions conducted. Workers often stand for extended periods and may need to lift packages of varying weights. The pace can be demanding during peak production periods, requiring physical stamina and mental focus. Many companies emphasize teamwork and provide opportunities for skill development through on-the-job training programs. Modern facilities often incorporate ergonomic design principles to reduce physical strain and improve working conditions.

Required knowledge in the field of cosmetic packaging

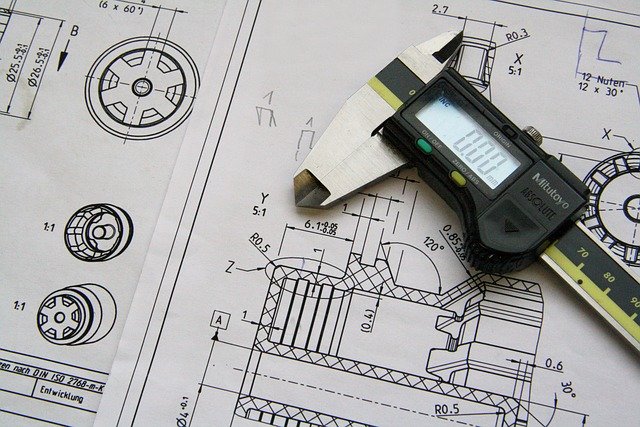

Entry-level positions in cosmetic packaging typically require basic technical aptitude and willingness to learn specialized processes. Workers benefit from understanding hygiene protocols, quality control procedures, and safety regulations specific to cosmetics manufacturing. Familiarity with packaging machinery operation, though often provided through training, can be advantageous. Basic mathematical skills help with inventory management and production tracking. Communication abilities are important for coordinating with team members and reporting quality issues. Some positions may require knowledge of different packaging materials and their properties. Understanding regulatory requirements for cosmetic products, including labeling standards and traceability procedures, enhances career prospects. Computer literacy is increasingly valuable as many facilities use digital systems for inventory management and quality tracking.

The cosmetic packaging sector in Düsseldorf continues to evolve with technological advancements and changing consumer preferences. Automation has transformed many traditional packaging processes while creating new opportunities for technically skilled workers. Sustainability initiatives have introduced eco-friendly packaging materials and processes, requiring workers to adapt to new methods and materials. The industry’s growth trajectory suggests continued demand for skilled packaging professionals who can maintain quality standards while adapting to innovation.

Career progression opportunities exist for dedicated workers who demonstrate reliability and technical competence. Many companies offer advancement paths from entry-level packaging roles to supervisory positions, quality control specialist roles, or technical maintenance positions. Professional development through industry training programs and certifications can enhance career prospects and earning potential within this specialized field.

The integration of digital technologies in packaging operations has created demand for workers comfortable with computerized systems and data management. This technological shift represents both a challenge and an opportunity for current and prospective workers in the field. Companies increasingly value employees who can adapt to new technologies while maintaining the precision and attention to detail that cosmetic packaging requires.