Mechanical Engineering Training in London – Build Skills for Tomorrow

Mechanical engineering training in London is often described as a structured way to explore how technical and practical skills are developed for modern industry. This article provides an informative overview of how training programs in this field are typically organized, what types of subjects and hands-on activities are commonly included, and how learning paths are aligned with current engineering practices. It also outlines how local study options may help learners better understand mechanical systems, design principles, and applied problem-solving without implying guaranteed outcomes or specific career results. The content is purely informational and aims to clarify what mechanical engineering training in London usually covers and how it is presented to those interested in building skills for the future.

London’s mechanical engineering training ecosystem combines academic depth with practical experience. Whether you are starting out or upskilling, you will find structured pathways that emphasise scientific foundations, design and manufacturing skills, and the software and safety practices used across UK industries. Courses typically combine lectures, studio work, and lab sessions so you can build knowledge progressively while applying it to real components and systems.

How London programs are structured

Most programmes follow a staged model that begins with fundamentals and moves toward application. An Overview of how mechanical engineering training programs in London are typically structured includes full‑time BEng/MEng degrees, Higher National Certificates/Diplomas, degree apprenticeships, and targeted short courses for professional development. Delivery often blends lectures, problem‑based learning, and workshops. Assessment may include exams, lab reports, group projects, and a capstone design or research project. Modes vary—full‑time, part‑time, evening, and blended options—so learners can match study with work commitments.

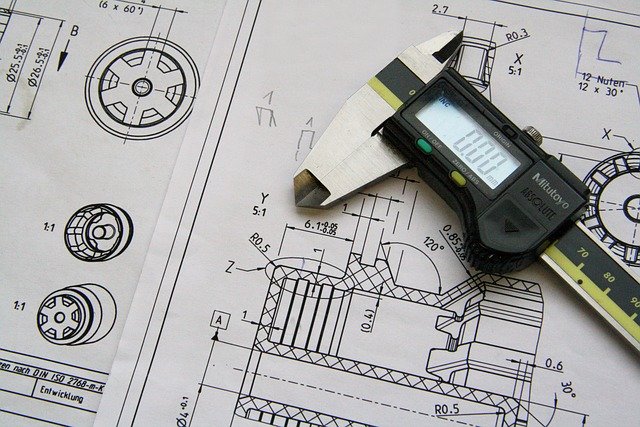

Subjects and hands‑on activities

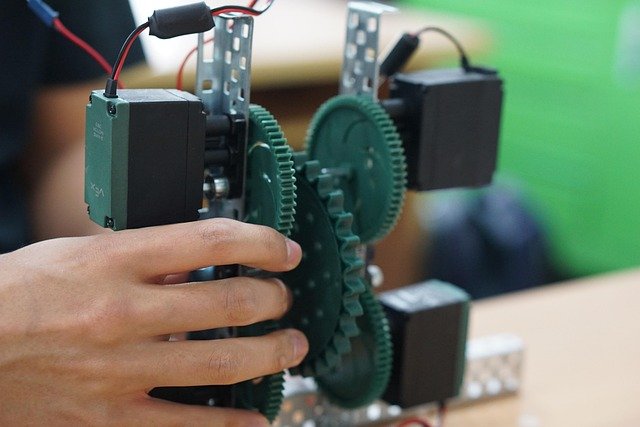

Common subjects and practical activities included in mechanical engineering study paths span statics, dynamics, thermodynamics, fluid mechanics, mechanics of materials, and control. Programmes often introduce electrical fundamentals, mechatronics, and data acquisition to connect mechanical systems with sensing and actuation. Workshop practice, machining, CNC basics, and additive manufacturing are used to translate models into parts. CAD and CAE skills—such as parametric modelling, drawings, finite element analysis, and simulation—are taught alongside lab sessions in materials testing, heat transfer rigs, and fluid flow benches. Design‑build‑test projects encourage teamwork and iteration.

Aligned with industry and standards

How training approaches align with current engineering practices and industry standards is a core priority in London. Many courses map learning outcomes to competencies expected by UK professional registration frameworks and incorporate health and safety practices consistent with national guidance. Students are exposed to design for manufacture and assembly, quality processes, and documentation conventions. Standards for technical drawings and tolerancing, risk assessment techniques, and lifecycle thinking are integrated through assignments and design reviews. Software commonly used in industry—such as mainstream CAD platforms, finite element tools, and MATLAB/Simulink—helps bridge learning with workplace tooling.

Design principles and problem solving

An Introduction to mechanical systems design principles and applied problem solving usually starts with clear requirements, constraints, and performance targets. Programmes teach concept generation, trade‑off analysis, and prototyping strategies, supported by tolerance analysis, reliability thinking, and basic failure modes and effects analysis. Students practise iterating between analytical models and experiments, validating assumptions with tests, and incorporating feedback from design reviews. Topics such as thermal management, vibration mitigation, mechanisms, and control integration develop the ability to design robust systems under real‑world constraints like cost, manufacturability, sustainability, and safety.

Local study options over time

The Role of local study options in developing technical understanding over time is significant in a city as large as London. Learners can combine part‑time university modules, evening classes at colleges, and short industrial courses to steadily build capability while working. Maker spaces, labs, and local services offering supervised workshop access help maintain practical skills. Professional societies and local events provide lectures, site visits, and networking that contextualise classroom learning. Over several semesters or years, this layered approach supports continuous development, portfolio growth, and confidence with tools and standards.

Bringing it together in real projects

Most London programmes culminate in projects that integrate analysis, design, and manufacture. Students define a problem, model system behaviour, produce drawings and documentation, select materials and processes, and create prototypes or digital twins. Collaboration with peers from electronics or computing disciplines reflects modern multidisciplinary practice. Emphasis on traceable requirements, verification plans, and clear documentation prepares learners to contribute to teams in design offices, test labs, or production environments. Reflection on lessons learned helps translate project experience into repeatable engineering processes.

Building software and data fluency

Training increasingly highlights digital skills alongside core mechanics. Students work with version control, simulation data management, and basic scripting to automate analysis. Exposure to sensor integration and simple control loops demonstrates how mechanical and software elements interact. Data logging from experiments is used to calibrate models, compare predicted and measured performance, and improve designs. This data‑aware mindset is valuable in roles that touch on digital manufacturing, condition monitoring, or sustainability analysis.

Safety, sustainability, and communication

Safety is embedded through risk assessments, method statements, and safe lab practices. Sustainability considerations encourage lifecycle thinking—material selection, energy efficiency, and end‑of‑life strategies. Equally important are communication and collaboration: concise reports, clear drawings, and presentations that align stakeholders. These skills support effective participation in reviews and help ensure that engineering intent is understood across procurement, manufacturing, and operations teams.

Progression and professional recognition

Learners can progress from foundational certificates to degrees and, with experience, to professional registration routes. Structured learning outcomes, lab competencies, and documented project work form a record of development. Engagement with professional bodies through lectures and local activities can guide longer‑term planning and align continuing professional development with evolving industry needs in the UK. Over time, this steady accumulation of skills supports deeper specialisation or broader systems roles.

In London, mechanical engineering training blends rigorous fundamentals with practical, standards‑aware learning. By combining structured curricula, hands‑on laboratories, design projects, and access to local services, learners build durable capabilities that translate to real engineering contexts. The emphasis on problem solving, documentation, and safety helps sustain relevance as tools and industry expectations evolve.