Mechanical Engineering Training in London: Skills Shaping Careers in 2025

Mechanical engineering training in London continues to evolve as new technologies influence how foundational and advanced skills are introduced to learners. This article provides an informative look at how topics such as 3D printing, robotics and sustainable design are commonly presented within training environments, and why they are discussed as part of the broader landscape shaping engineering practices in 2025. The content does not offer job placements or guaranteed career results, but aims to give readers a clear understanding of how these subjects are framed in educational contexts and how training programmes describe the competencies they seek to develop.

London remains a focal point for mechanical engineering training, with universities, colleges, and professional centres updating curricula to match rapid technological change. Learners encounter a blend of theory, laboratory practice, and project work that links classical mechanics to contemporary tools and methods. The approach in 2025 emphasises clear explanations of why certain technologies feature in modules, how they relate to established principles, and what realistic capabilities students can expect to develop. Programmes also clarify assessment strategies and progression routes, helping learners understand sequencing without suggesting assured job results.

How do London training materials introduce 3D printing, robotics and sustainable design?

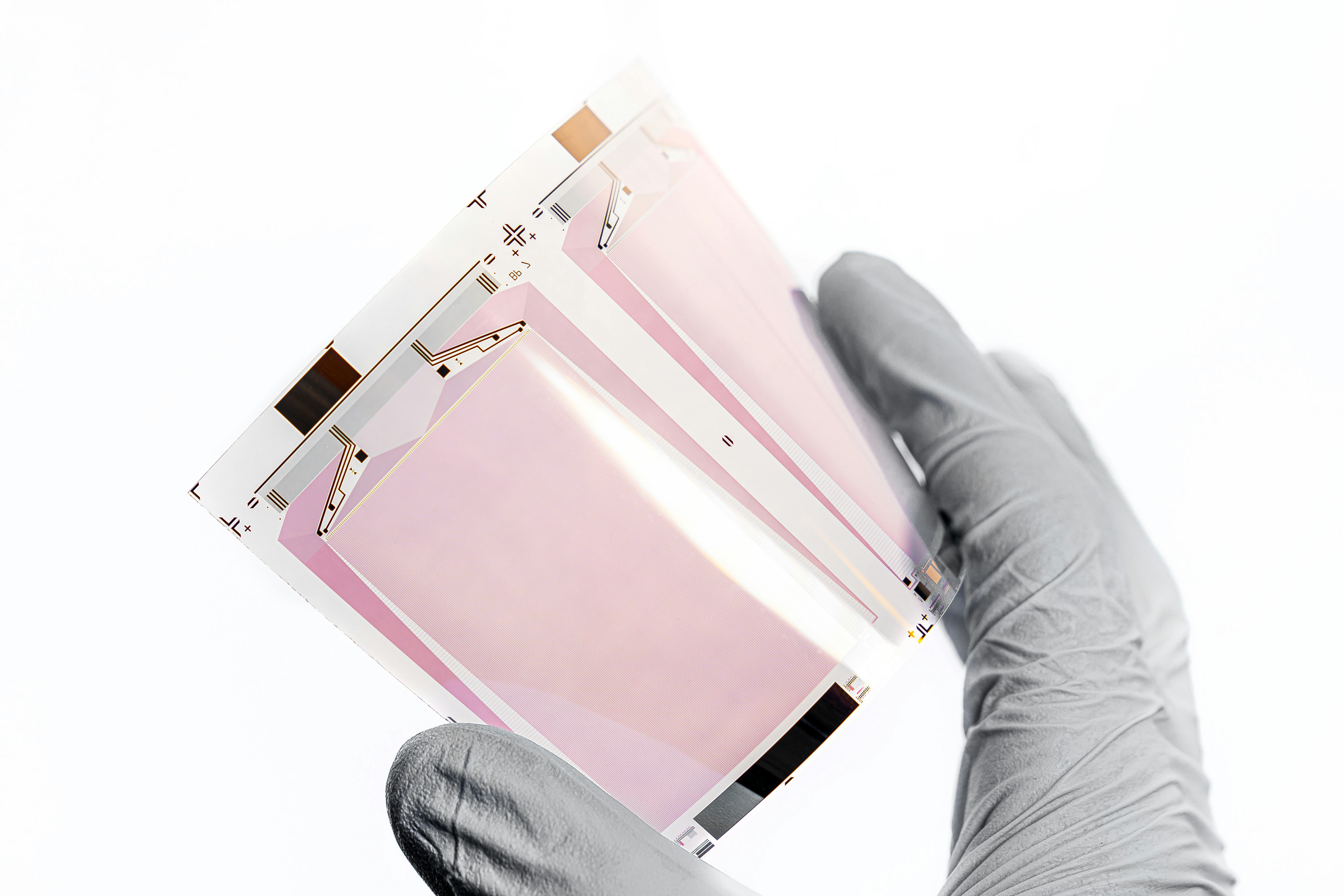

Training materials in London often describe how emerging technologies such as 3D printing, robotics and sustainable design are introduced within mechanical engineering programmes, typically through staged exposure. Early modules connect additive manufacturing to materials science and design-for-manufacture, moving from basic CAD modelling to hands-on prototyping with polymers and, where facilities allow, metals. Robotics content is commonly tied to dynamics and control, so learners see how kinematics, sensing, and actuation translate into robotic arms or mobile platforms. Sustainable design is framed through thermodynamics, life-cycle thinking, and energy efficiency, using case studies that show practical trade-offs between performance, cost, and environmental impact.

How are subjects structured in educational overviews without promising outcomes?

Educational overviews explain how these subjects are structured to help learners understand their relevance in modern engineering contexts without promising career outcomes. Syllabi typically map foundational topics—statics, dynamics, fluid mechanics, and materials—to later specialisms such as mechatronics, advanced manufacturing, or energy systems. This sequencing helps learners see prerequisite knowledge, laboratory milestones, and project phases. Assessment methods—design reports, lab notebooks, simulation assignments, and presentations—are outlined to make expectations transparent. Many providers also describe optional workshops and local services like maker spaces or industry seminars “in your area” as enrichment rather than guarantees of placement, clarifying that participation strengthens understanding but does not assure specific employment results.

Why are these themes central to engineering practice in 2025?

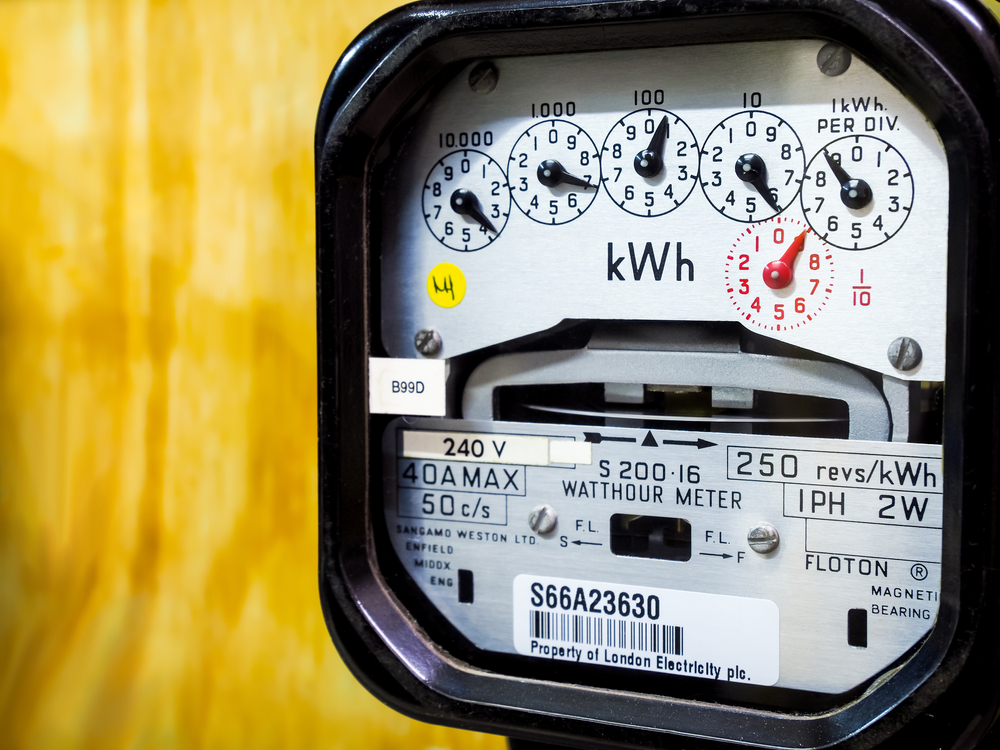

Informative analyses illustrate why these technological themes are discussed as part of the broader landscape shaping engineering practices in 2025. Additive manufacturing changes how engineers prototype, customise, and repair components, influencing cost models and design constraints. Robotics affects production quality and safety, while enabling higher precision in repetitive or hazardous tasks. Sustainability cuts across disciplines, affecting materials selection, energy use, and system lifetimes. London’s training providers present these areas as interdependent rather than isolated innovations. For example, a sustainable product redesign may pair a lightweight lattice printed via additive processes with control strategies that reduce energy usage—demonstrating how modern decisions draw on multiple competencies at once.

How do programme descriptions present core and advanced competencies?

Programme descriptions outline how core and advanced competencies are presented to support a clearer understanding of evolving mechanical engineering skills. Core competencies remain central: mathematical methods, mechanics, thermodynamics, materials characterisation, and manufacturing processes. These are complemented by CAD/CAE, coding for simulation and data analysis, and experimental methods that emphasise uncertainty and repeatability. Advanced competencies build on that base: mechatronics, machine vision, embedded control, additive manufacturing workflows, digital twins, and sustainability assessment tools. Descriptions often highlight teamwork, communication, and documentation standards, showing how professional practice depends on traceability, risk management, and ethical considerations such as responsible use of automation and environmentally conscious design.

In practical terms, London-based curricula aim to connect classroom theory with real equipment and software environments. Many laboratories integrate sensors, microcontrollers, and simple actuators to link control theory to physical prototypes. Simulation platforms are used to validate design assumptions before fabrication, teaching learners to interpret model limitations. Safety protocols, equipment maintenance basics, and workshop etiquette are emphasised, reflecting the responsibilities engineers face on production floors and in test facilities. By aligning laboratory tasks with documented procedures, programmes cultivate habits that translate to regulated engineering settings.

Another feature of 2025 training is transparency about the pace of technological change. Course guides increasingly explain that tools and platforms may update during an academic cycle, and that learners should be prepared to translate principles across software versions or hardware revisions. This message supports the development of adaptive thinking: understanding the underlying physics and control strategies first, then applying them in whichever toolset is current. Where guest talks or case studies are used, they typically focus on decision-making frameworks—such as design for manufacturability, failure analysis, or life-cycle costing—rather than product promotions, helping learners separate durable concepts from transient features.

Project work continues to serve as the bridge between competencies. Capstone or group projects often require integrating design, analysis, fabrication, and testing within realistic constraints, such as time, budget, safety, and sustainability. Briefs may include building a robotic subsystem, redesigning a heat exchanger for higher efficiency, or validating a lightweight structure with finite element analysis followed by a physical test. Supervisors encourage clear documentation, version control for models, and basic verification plans, so that results are reproducible and critiques are constructive. Reflection sections in reports help learners articulate how choices in materials, geometry, or control laws affected outcomes and what trade-offs were encountered.

For those reviewing local course options, programme descriptors generally clarify entry expectations and support available for different backgrounds. Bridging materials—mathematics refreshers, programming primers, and lab skills introductions—are often described as optional pathways to help learners progress through early modules. In 2025, written guides also emphasise inclusivity in design and team processes, noting how varied perspectives can improve requirements gathering and risk identification. By making these dimensions explicit, training materials help learners build a practical understanding of how engineering decisions are made in multidisciplinary teams.

Ultimately, mechanical engineering training in London this year is characterised by careful explanations that connect foundational science to current technologies, without implying specific outcomes beyond learning. The emphasis on 3D printing, robotics, and sustainable design reflects wider changes in practice, while the structure of modules, assessments, and projects aims to develop sound judgement and transferable technical skills. The result is a clearer view of what is taught, why it matters, and how competencies can evolve as tools and methods continue to change.