Mechanical Engineering Training in London: Skills Shaping Careers in 2025

Mechanical engineering training in London is frequently highlighted as a pathway through which learners can explore the technical and practical skills shaping the industry in 2025. This article offers a clear overview of how such programmes are commonly described, from foundational engineering principles to hands-on methods that support understanding of modern industrial technologies. The aim is to provide readers with an informative perspective on the competencies often associated with this field. The content is strictly educational and does not include enrolment options, career promises or guidance on professional outcomes, but rather explains how training initiatives are presented in publicly available sources.

The mechanical engineering training sector in London has undergone significant transformation as educational institutions respond to rapidly changing industry requirements. Training programmes across the capital now blend time-tested engineering principles with emerging technologies, creating comprehensive learning experiences that prepare students for diverse career pathways.

Overview of Foundational Engineering Concepts and Practical Methods

Mechanical engineering training in London typically encompasses core subjects including thermodynamics, fluid mechanics, materials science, and structural analysis. Training providers commonly present these fundamentals through a combination of theoretical instruction and laboratory work. Students engage with mathematical modelling, computer-aided design software, and physical testing procedures that form the backbone of mechanical engineering practice.

Most programmes emphasise problem-solving methodologies, teaching systematic approaches to engineering challenges. These foundational elements remain consistent across different training providers, though delivery methods may vary from traditional lectures to interactive workshops and project-based learning.

Modern Technologies in Evolving Skill Development

Contemporary mechanical engineering training increasingly incorporates advanced technologies that reflect current industry trends. Robotics instruction has become a standard component, with students learning programming languages, sensor integration, and automated system design. Training materials frequently highlight how robotic systems apply mechanical principles in manufacturing, healthcare, and transportation sectors.

3D printing technology features prominently in modern curricula, with students exploring additive manufacturing processes, material properties, and design optimisation techniques. Sustainable design principles are also emphasised, covering renewable energy systems, environmental impact assessment, and resource-efficient engineering solutions.

Artificial intelligence and machine learning applications in engineering design are becoming common topics, reflecting the integration of digital technologies with traditional mechanical systems.

Competencies Associated with Mechanical Engineering Pathways

Training programmes typically frame mechanical engineering competencies around several key areas. Technical skills encompass proficiency with industry-standard software such as CAD programmes, finite element analysis tools, and simulation software. Students develop expertise in manufacturing processes, quality control procedures, and project management methodologies.

Communication skills receive considerable emphasis, with programmes highlighting the importance of technical writing, presentation abilities, and collaborative teamwork. Many training descriptions emphasise critical thinking and analytical reasoning as essential competencies for addressing complex engineering problems.

Professional development components often include understanding of regulatory frameworks, safety standards, and ethical considerations in engineering practice. These competencies are presented as integral to successful engineering careers across various industries.

Hands-On Instruction and Technical Learning Approaches

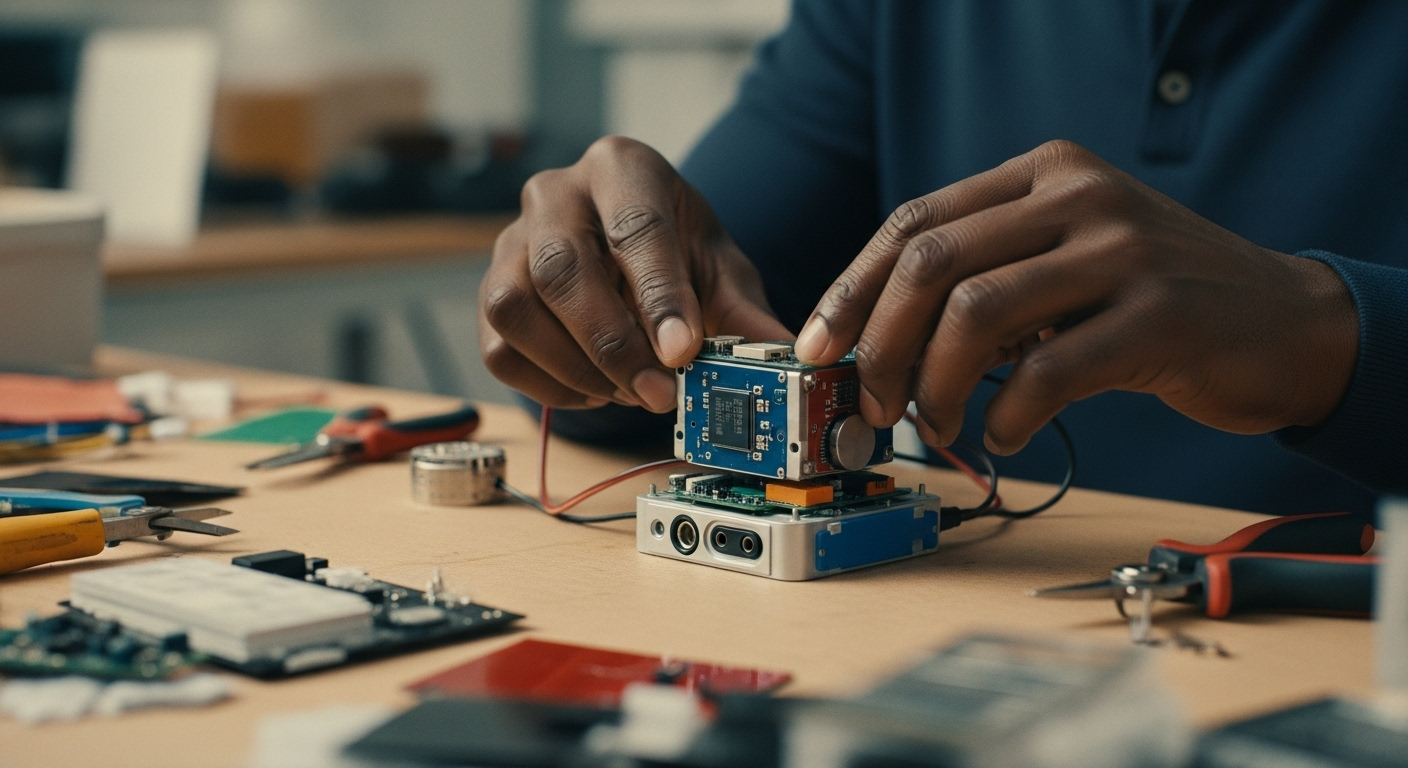

Publicly available materials consistently emphasise the importance of practical learning experiences in mechanical engineering training. Laboratory sessions typically feature materials testing, prototype development, and equipment operation under supervised conditions. Workshop environments allow students to gain experience with machining, welding, and assembly techniques.

Many programmes incorporate industry partnerships that provide access to real-world engineering challenges and modern equipment. These collaborations are often presented as opportunities for students to apply theoretical knowledge in practical contexts while developing familiarity with current industry practices.

Project-based learning approaches are frequently highlighted, with students working on design challenges that mirror professional engineering scenarios. These experiences typically involve research, planning, implementation, and evaluation phases that reflect actual engineering project workflows.

| Training Provider | Programme Focus | Key Features | Duration |

|---|---|---|---|

| Imperial College London | Advanced Engineering | Research facilities, industry partnerships | 1-4 years |

| University College London | Mechanical Systems | Hands-on laboratories, modern equipment | 1-3 years |

| King’s College London | Engineering Design | Project-based learning, CAD training | 6 months-2 years |

| London South Bank University | Practical Engineering | Workshop training, industry connections | 1-3 years |

| City, University of London | Technical Applications | Professional development, certification | 6 months-2 years |

General Informational Context and Training Initiative Summaries

This analysis draws from publicly available descriptions of mechanical engineering training programmes and does not constitute career guidance or professional guarantees. Training approaches vary significantly between providers, and programme content evolves regularly to reflect technological advances and industry requirements.

Educational materials typically present mechanical engineering training as preparation for diverse career paths including automotive design, aerospace engineering, renewable energy systems, and manufacturing management. However, career outcomes depend on numerous factors including individual performance, market conditions, and specific industry requirements.

Prospective students are encouraged to research specific programme requirements, accreditation status, and career support services when evaluating training options. Industry trends and skill requirements continue to evolve, making ongoing professional development an important consideration for engineering careers.

The mechanical engineering training landscape in London reflects broader technological and industrial changes, with programmes adapting to incorporate emerging technologies while maintaining focus on fundamental engineering principles. This balance between traditional knowledge and modern applications characterises the current approach to mechanical engineering education across the capital’s training providers.