Overview of food packaging jobs in Southwark

Individuals residing in Southwark can gain insights into the nature of work in food packing warehouses. This involves understanding the specific conditions and standards that govern these environments. The exploration includes daily tasks, responsibilities, and the overall atmosphere of food packing operations, which are essential for ensuring quality and efficiency in food distribution.

Food packaging constitutes an important component of Southwark’s industrial sector. This London borough, with its strategic location and transport connections, has historically been home to various food processing and packaging operations. These range from smaller artisanal facilities to larger industrial complexes that serve the broader London market. This article examines the general characteristics of food packaging work in Southwark, providing information about typical environments, responsibilities, and industry standards rather than specific employment opportunities.

Understanding the Environment of Food Packing Warehouses in Southwark

Food packing warehouses in Southwark typically operate within specific parameters designed to maintain food safety and quality. These facilities generally feature climate-controlled environments, particularly important for operations handling perishable goods. Temperature regulation serves dual purposes—ensuring food safety standards while creating workable conditions in spaces where repetitive tasks are common.

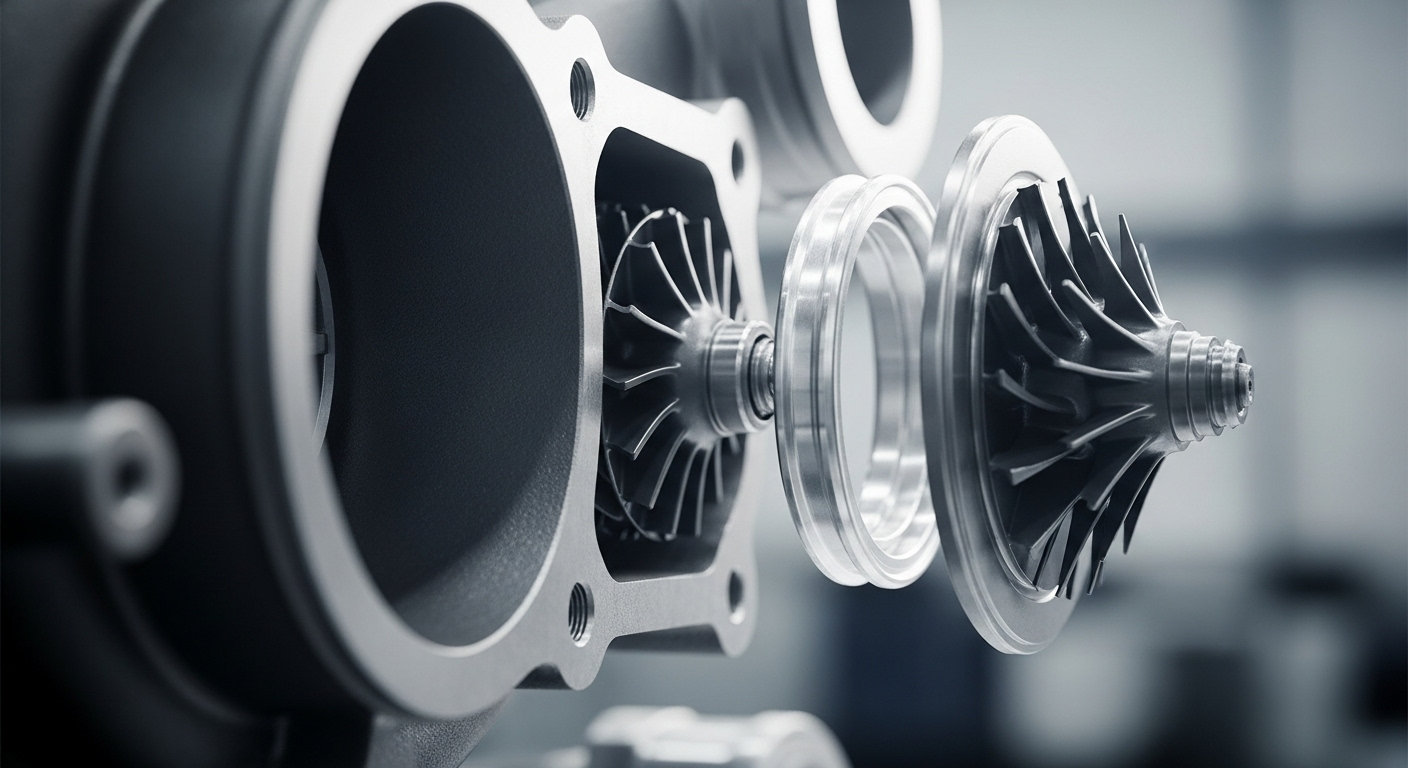

The physical layout of these warehouses generally includes designated areas for receiving raw materials, storage sections organized by product type, packaging lines with various stations, quality control checkpoints, and dispatch zones. Modern facilities in the Southwark area often incorporate a combination of manual processes and automated systems, reflecting the industry’s gradual technological evolution while maintaining traditional packaging methods where appropriate.

Key Responsibilities and Daily Tasks in Food Packing Roles

Roles within food packaging encompass various responsibilities depending on position and facility type. Common functions in this industry typically include product sorting, machinery operation, labeling, and preparation for distribution. More specialized positions might involve quality assurance, equipment maintenance, or line supervision.

Typical tasks associated with food packaging work include:

- Product inspection for quality assurance before packaging processes begin

- Operation of packaging equipment such as wrapping machines, sealers, or labeling devices

- Manual packaging for items requiring careful handling or special attention

- Weight verification to ensure consistent portioning

- Maintaining sanitary conditions throughout work areas

- Checking finished packages for proper sealing and presentation

- Preparing completed packages for shipping or distribution

- Documentation of production data and quality metrics

Industry practices often involve rotation between different workstations during shifts to reduce physical strain from repetitive motions, though some workers may develop specialization in particular packaging processes.

Safety Standards and Working Conditions in Food Packing Facilities

The food packaging industry operates under strict regulatory frameworks established by UK food safety legislation and local health authorities. Standard protocols generally include requirements for protective clothing such as hairnets, gloves, and appropriate workwear. Hygiene procedures typically mandate regular handwashing and sanitization, with many facilities featuring dedicated changing areas where street clothing must be exchanged for clean work attire.

The physical working environment commonly involves extended periods of standing, sometimes in temperature-controlled settings for refrigerated products. Noise levels vary based on the machinery in operation. Industry standards typically include scheduled breaks and designated rest areas separate from production zones.

Standard safety and working condition elements include:

- Alignment with Food Standards Agency (FSA) regulations

- Implementation of HACCP (Hazard Analysis Critical Control Point) systems

- Ongoing safety training programs

- Ergonomic considerations to minimize repetitive strain

- Established emergency procedures and first aid provisions

- Environmental controls appropriate to food product requirements

Qualifications and Skills Associated with Food Packaging Work

The food packaging industry generally features varied entry requirements. While formal qualifications may not be mandatory for many positions, certain skills and attributes are typically valued across the sector.

Basic numeracy and literacy skills are generally important, particularly for roles involving weight verification, instruction following, or record-keeping. Physical stamina is typically necessary as the work often involves standing for extended periods and may require lifting. Attention to detail represents a crucial quality for maintaining standards and identifying potential product or packaging issues.

Food hygiene certifications such as Level 2 Food Safety and Hygiene for Manufacturing can enhance qualifications in this field. Experience with specific packaging equipment or previous food handling work may be beneficial, though on-the-job training is commonly provided throughout the industry.

Career Development in the Food Packaging Industry

The food packaging sector presents various pathways for professional development. Industry knowledge indicates that workers often begin in general packaging positions before potentially advancing to quality control functions, team coordination, or specialized equipment operation. With experience and additional training, progression to supervisory or operational management roles represents a possible career trajectory.

The industry generally demonstrates relative stability due to consistent demand for packaged food products. Seasonal variations do occur within the sector, with holiday periods often creating fluctuations in production requirements. Core positions typically offer regular schedules, while temporary arrangements may expand during peak production periods.

The essential nature of food production and distribution has historically demonstrated resilience during various economic conditions. Southwark’s proximity to central London markets and distribution networks contributes to the ongoing presence of food packaging operations in the area.

Conclusion

Food packaging represents an established component of Southwark’s industrial landscape. These roles typically require attention to detail, physical endurance, and adherence to strict hygiene protocols rather than extensive formal qualifications. The sector features standardized practices and regulatory requirements that shape working environments across different facilities. Understanding these industry characteristics provides context for those interested in learning about this aspect of Southwark’s industrial heritage and current economic composition.