Portable laser welders improve accuracy and efficiency in Japan

In Japan, portable laser welders are transforming the welding landscape, improving precision, saving time, and reducing costs. This technology is particularly beneficial in several sectors, including manufacturing and construction. A closer look at the different models, pricing structures, and practical applications reveals their growing importance in welding manufacturing processes. Furthermore, effective welding training for workers is essential to maximize the potential of these advanced machines.

Japan’s industrial landscape continues to evolve with cutting-edge welding technologies that transform manufacturing processes. Portable laser welding machines represent a significant advancement in metalworking capabilities, offering manufacturers enhanced precision and operational flexibility that traditional welding methods cannot match.

How Portable Laser Welding Machines Work

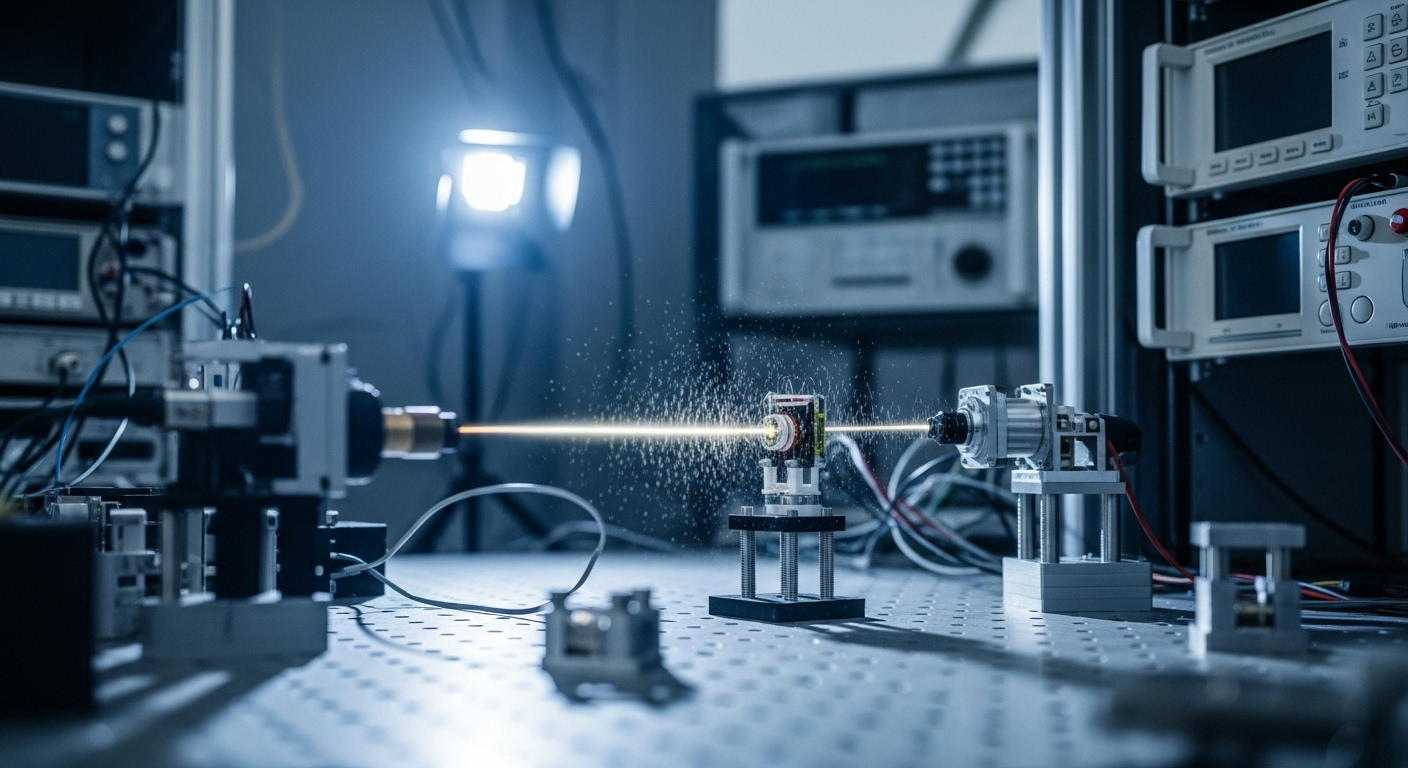

Portable laser welding systems utilize concentrated laser beams to melt and fuse metal materials with exceptional precision. The process begins when a high-powered laser generates an intense beam of light that focuses on a small area, typically measuring just a few millimeters in diameter. This concentrated energy rapidly heats the metal to its melting point, creating a molten pool that solidifies upon cooling to form a strong weld joint.

The portable design incorporates fiber laser technology, which transmits the laser beam through flexible optical fibers to a handheld welding head. This configuration allows operators to maneuver easily around complex workpieces and access tight spaces that would be impossible with stationary welding equipment. The system includes cooling mechanisms, power controls, and safety features integrated into a compact, mobile unit.

Advantages of Portable Laser Welding in Japanese Industry

Japanese manufacturers have discovered numerous benefits when implementing portable laser welding technology. The precision offered by these systems significantly reduces material waste, as the focused laser beam creates minimal heat-affected zones compared to traditional arc welding methods. This precision proves particularly valuable in industries requiring tight tolerances, such as electronics and precision machinery manufacturing.

The efficiency gains are substantial, with welding speeds often 2-5 times faster than conventional methods. The reduced heat input minimizes warping and distortion, eliminating many post-welding correction processes. Additionally, the clean welding process produces minimal spatter and requires less post-weld cleaning, streamlining production workflows.

Operational flexibility represents another key advantage. The portable nature allows welding operations in various locations without requiring workpiece transportation to fixed welding stations. This mobility proves especially beneficial for repair work, on-site installations, and small-batch production runs.

Applications of Laser Welding in Various Industrial Sectors

Japan’s automotive industry has widely adopted portable laser welding for manufacturing precision components, including fuel injection systems, transmission parts, and electronic control modules. The technology excels in welding dissimilar metals, enabling manufacturers to combine different materials for optimal performance characteristics.

The electronics sector utilizes these systems for welding delicate components in smartphones, computers, and consumer electronics. The precise heat control prevents damage to sensitive electronic components while creating reliable electrical connections. Medical device manufacturing also benefits from the clean, precise welds required for surgical instruments and implantable devices.

Aerospace applications include welding titanium and aluminum components where strength-to-weight ratios are critical. The technology’s ability to create consistent, high-quality welds meets the stringent quality requirements of aerospace manufacturing standards.

| Machine Type | Manufacturer | Power Range | Cost Estimation |

|---|---|---|---|

| Handheld Fiber Laser | Trumpf | 1000-2000W | ¥2,500,000-¥4,500,000 |

| Portable Laser System | IPG Photonics | 1500-3000W | ¥3,000,000-¥6,000,000 |

| Mobile Welding Unit | Coherent | 1000-2500W | ¥2,800,000-¥5,200,000 |

| Compact Laser Welder | Rofin-Sinar | 800-2000W | ¥2,200,000-¥4,000,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The adoption of portable laser welding technology continues to expand across Japan’s manufacturing sectors as companies recognize the long-term benefits of improved quality, reduced production costs, and enhanced operational flexibility. While the initial investment remains significant, the technology’s ability to improve product quality while reducing production time and material waste makes it an attractive option for manufacturers seeking competitive advantages in global markets. As laser technology continues advancing and costs decrease, portable laser welding systems are expected to become increasingly accessible to smaller manufacturers and specialized fabrication shops throughout Japan.