Portable Laser Welding Machines Enhance Precision and Efficiency in United States

In United States, portable laser welding machines are transforming the welding landscape by enhancing precision, saving time, and reducing costs. This technology is particularly beneficial in various sectors, including manufacturing and construction. A closer look at different models, pricing structures, and practical applications reveals their growing significance in welding fabrication processes. Additionally, effective welding training for workers is essential to maximize the potential of these advanced machines.

Portable laser welding machines represent a significant advancement in welding technology across the United States. These compact yet powerful devices are changing how industries approach metal joining operations by offering superior precision, reduced heat-affected zones, and the ability to work with a diverse range of materials and thicknesses. The technology utilizes concentrated laser beams to create strong, clean welds with minimal distortion, making it particularly valuable for applications requiring high aesthetic quality and structural integrity. As American manufacturing continues to evolve toward more specialized and high-precision work, portable laser welders are becoming essential tools for maintaining competitive advantage in global markets.

Understanding Portable Laser Welding Machines and Their Benefits

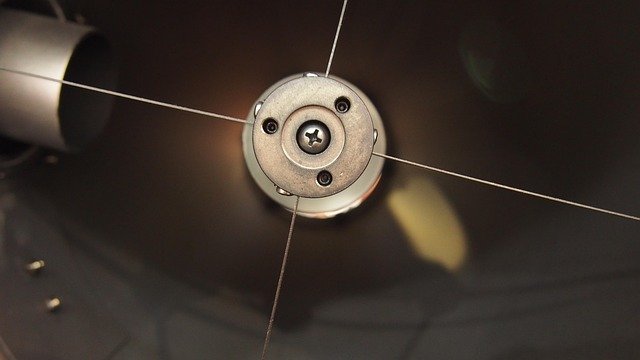

Portable laser welding machines operate by generating a highly concentrated beam of light that creates a precise heat source when focused on metal surfaces. Unlike traditional welding methods that produce widespread heat, laser welding creates a narrow, controlled heat-affected zone that minimizes material distortion. This precision makes these machines ideal for delicate applications where maintaining dimensional accuracy is critical. Modern portable units typically use fiber lasers, which offer excellent beam quality, energy efficiency, and reliability in a compact form factor.

The benefits of portable laser welding extend beyond precision alone. These machines significantly increase productivity through faster welding speeds and reduced post-weld cleanup. Many models feature automated controls that maintain consistent weld quality regardless of operator experience, addressing the skilled labor shortage facing many American manufacturing sectors. Additionally, the non-contact nature of laser welding eliminates the need for consumable electrodes and shielding gases required by conventional methods, resulting in operational cost savings over time.

Portability represents another crucial advantage in today’s flexible manufacturing environments. Weighing significantly less than traditional welding equipment, these machines can be easily transported between job sites or different areas within a facility. Some advanced models incorporate battery power options, further enhancing mobility for field operations. This portability, combined with precision capabilities, makes laser welding accessible for industries ranging from automotive repair to aerospace component manufacturing throughout the United States.

Applications of Welding Fabrication in Various Industries

The automotive industry has embraced portable laser welding for both manufacturing and repair applications. In production environments, these machines excel at joining thin-gauge metals used in body panels and structural components with minimal heat distortion. Auto repair shops increasingly utilize portable laser welders for precision repairs on high-value vehicles where maintaining original specifications is paramount. The technology allows technicians to perform repairs that were previously impossible without replacing entire panels, saving time and materials while preserving vehicle integrity.

Aerospace manufacturing represents another sector where portable laser welding machines have made significant inroads. The industry’s stringent quality requirements and use of specialized alloys make laser welding particularly valuable. Components for aircraft engines, structural elements, and fuel systems benefit from the precision and consistency that laser technology provides. American aerospace manufacturers have reported substantial improvements in component quality and reduced rejection rates after implementing portable laser welding in their production processes.

The medical device industry has similarly adopted portable laser welding for manufacturing implantable devices, surgical instruments, and diagnostic equipment. The ability to create hermetically sealed joints with minimal thermal impact makes laser welding ideal for sensitive medical applications. Additionally, jewelry manufacturing, electronics production, and energy sector fabrication have all found valuable applications for portable laser welding technology. As these machines become more accessible to small and medium-sized businesses across the United States, their application continues to expand into new industries and specialized niches.

Importance of Welding Training for Workers

Despite the automated features of modern portable laser welding machines, proper training remains essential for operators to maximize the technology’s potential. Specialized knowledge regarding parameter selection, material properties, and safety protocols is critical for achieving optimal results. Recognizing this need, technical schools and community colleges throughout the United States have begun incorporating laser welding into their curriculum. These programs typically combine theoretical knowledge with hands-on practice using industry-standard equipment.

Safety training deserves particular emphasis when working with laser technology. Unlike traditional welding, where risks are primarily related to heat, sparks, and fumes, laser welding introduces potential hazards from invisible radiation. Proper eye protection specifically designed for the wavelength of the laser being used is mandatory, as are protocols for safe operation and maintenance. Many manufacturers offer specialized training programs when organizations purchase their equipment, ensuring operators understand both the capabilities and safety requirements of the technology.

Continuing education plays a vital role as laser welding technology evolves rapidly. Experienced welders transitioning to laser technology often need to unlearn certain practices associated with traditional methods while developing new skills specific to laser operation. Professional organizations like the American Welding Society now offer certification programs focused on laser welding, providing workers with credentials that validate their specialized knowledge. These certifications are increasingly valued by employers seeking to maintain quality standards and competitive advantages in their respective industries.

Comparing Portable Laser Welding Machine Options

| Manufacturer | Model | Power Output | Key Features | Cost Estimation |

|---|---|---|---|---|

| IPG Photonics | LightWELD 1500 | 1500W | Handheld design, built-in vision system | $100,000-$125,000 |

| Coherent | CleanWeld 1000 | 1000W | Wobble welding capability, programmable patterns | $85,000-$110,000 |

| Trumpf | TruLaser Weld 1000 | 1000W | Seam tracking, automated parameter selection | $90,000-$120,000 |

| nLIGHT | Corona 500 | 500W | Compact design, rapid setup, touchscreen interface | $65,000-$80,000 |

| SPI Lasers | redPOWER 500 | 500W | Multiple weld modes, integrated cooling | $60,000-$75,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Future Trends in Portable Laser Welding Technology

The future of portable laser welding in the United States points toward greater accessibility and capability. Manufacturers are actively developing more affordable entry-level systems to bring laser welding within reach of smaller fabrication shops and specialized repair businesses. These systems maintain core precision advantages while simplifying operations for users with limited technical expertise. Additionally, advancements in battery technology are enabling truly cordless operation for extended periods, making these machines viable for remote field applications where power availability has traditionally been a limitation.

Artificial intelligence and machine learning integration represents another significant trend in the evolution of portable laser welding. Next-generation machines are incorporating sensors that monitor weld quality in real-time, automatically adjusting parameters to compensate for material variations or environmental conditions. Some systems can now “learn” from previous welds to optimize future operations, reducing the expertise barrier for new operators. These smart features are particularly valuable in addressing the skilled labor shortage facing many American manufacturing sectors.

As sustainability concerns grow across industries, portable laser welding is positioned favorably due to its energy efficiency and reduced material waste. The precision of laser welding minimizes the need for post-weld machining and finishing, reducing overall resource consumption. Additionally, the ability to repair rather than replace components contributes to extended product lifecycles. These environmental advantages, combined with operational efficiencies, suggest that portable laser welding technology will continue gaining adoption throughout American manufacturing and repair industries as companies balance productivity, quality, and sustainability goals in their operations.