Technical Training in Sydney – Practical Skills for Innovation and Digital Industry

Sydney, Australia's largest economic hub and a center for digital and creative industries, offers leading technical training programs essential for the modern workforce. These courses emphasize a practical, hands-on learning approach, helping students develop real-world competencies in software engineering, project management, and digital infrastructure. These programs are vital for fueling the next generation of skilled professionals in New South Wales.

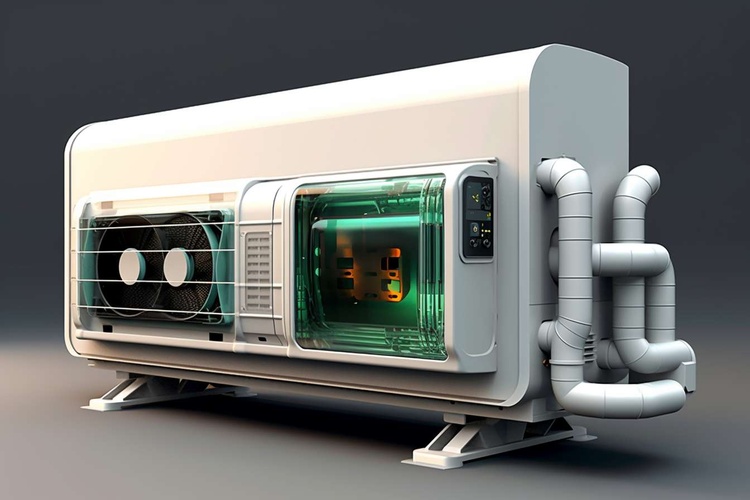

The mechanical engineering field continues to transform as digital technologies and automation reshape industrial processes across Australia. Sydney has emerged as a hub for technical education that responds directly to these changes, offering specialized training programs that combine traditional mechanical engineering principles with modern digital competencies. This integration creates well-rounded professionals capable of addressing complex engineering challenges while contributing to innovation across manufacturing, energy, transportation, and other vital sectors.

How Practical and Accessible Programs Support Career Development

Technical training institutions across Sydney have redesigned their mechanical engineering curricula to emphasize accessibility and practical application. These programs typically feature modular learning paths that allow students to build competencies progressively while maintaining professional commitments. Evening classes, weekend workshops, and hybrid learning models have become standard offerings, making advanced technical education available to career-changers, working professionals seeking upskilling opportunities, and recent graduates alike.

The accessibility extends beyond scheduling flexibility to include entry pathways that recognize prior learning and work experience. Many programs offer bridging courses for those without traditional engineering backgrounds, creating diverse cohorts that enrich the learning environment through varied perspectives and experiences. This approach has proven particularly valuable for addressing skills gaps in specialized areas like renewable energy systems, advanced manufacturing, and industrial automation.

Industry-Oriented Approach to Engineering Education

Sydney’s leading technical institutes have developed their mechanical engineering programs in close collaboration with industry partners, ensuring curriculum alignment with actual workplace requirements. This industry-oriented approach manifests through multiple channels, including regular curriculum reviews by practicing engineers, guest lectures from industry experts, and problem-based learning scenarios derived from real industrial challenges.

The integration extends to work-integrated learning opportunities, where students tackle actual engineering projects for partner companies. These experiences provide invaluable context for technical concepts while developing the professional communication, project management, and teamwork capabilities essential in modern engineering environments. Many programs culminate in capstone projects sponsored by industry partners, allowing students to demonstrate their technical mastery while solving authentic engineering problems.

Developing Up-to-Date Technical Skills for Digital Manufacturing

As manufacturing processes become increasingly digitized, mechanical engineering training has evolved to incorporate the technical skills required for Industry 4.0 environments. Sydney’s technical institutes now offer specialized modules covering computational fluid dynamics, finite element analysis, digital twins, and predictive maintenance systems. These advanced technical components are taught using the same software platforms and analytical tools employed in industry settings.

Programming and data analysis have become core components of mechanical engineering training, with courses covering Python, MATLAB, and specialized engineering software packages. Students learn to develop simulation models, analyze sensor data from mechanical systems, and implement machine learning algorithms for predictive maintenance applications. This technical foundation prepares graduates to work effectively in smart manufacturing environments where digital and physical systems are deeply integrated.

Labs with Modern Equipment: The Foundation of Practical Learning

The quality of technical training depends significantly on the facilities available for hands-on practice. Sydney’s engineering institutes have invested substantially in laboratory infrastructure that mirrors contemporary industrial environments. These facilities typically include advanced manufacturing equipment such as CNC machines, 3D printers, robotics systems, and automated assembly lines. Students gain direct experience with industrial-grade equipment, learning operational procedures, maintenance protocols, and troubleshooting techniques.

Modern mechanical engineering labs also feature extensive instrumentation for testing and measurement, allowing students to conduct material analysis, stress testing, thermodynamic experiments, and fluid dynamics investigations. Data acquisition systems connected to these experimental setups provide students with experience in collecting, processing, and interpreting engineering data – skills directly transferable to industrial settings where evidence-based decision-making is paramount.

Learning from Tutors with Professional Engineering Experience

The effectiveness of technical training depends heavily on the instructors’ ability to connect theoretical concepts with practical applications. Sydney’s engineering programs prioritize recruiting teaching staff with substantial industry experience, creating learning environments where theory is consistently contextualized through real-world examples. These experienced tutors bring case studies from their professional careers into the classroom, illustrating how engineering principles apply in different industrial contexts.

Many programs employ a mixed staffing model, combining full-time academics with practicing engineers who teach specialized modules. This approach ensures students benefit from both research-informed teaching and current industry insights. The involvement of practicing engineers also creates valuable networking opportunities for students, often leading to internships, project collaborations, and employment opportunities upon graduation.

Technical Training Providers in Sydney: Comparison of Key Features

| Institution | Program Duration | Specialization Options | Industry Partnerships | Advanced Equipment Access |

|---|---|---|---|---|

| University of Technology Sydney | 3-4 years (degree) | Robotics, Renewable Energy, Biomedical | Siemens, ResMed, Transport NSW | Advanced Manufacturing Precinct |

| TAFE NSW | 6 months - 2 years | Manufacturing, HVAC, Maintenance | BlueScope Steel, Downer Group | Industrial Skills Centre |

| Sydney Institute of Technology | 2-3 years | Automation, CAD/CAM, Aerospace | Boeing, Thales, BAE Systems | Aerospace Technology Lab |

| Engineering Institute of Australia | 1-2 years (postgrad) | Digital Manufacturing, IoT Integration | Cochlear, CSR Limited | Industry 4.0 Training Centre |

The technical training landscape in Sydney offers diverse pathways for aspiring mechanical engineers, with programs ranging from vocational certificates to advanced degrees. When selecting a program, prospective students should consider factors beyond course content, including the quality of laboratory facilities, industry connections, and the professional experience of teaching staff. Many institutions offer information sessions and facility tours that provide valuable insights into their teaching approach and available resources.

Sydney’s approach to mechanical engineering training continues to evolve, responding to technological changes and industry requirements. The integration of digital competencies with traditional mechanical engineering principles creates graduates who can contribute effectively across diverse sectors – from renewable energy and sustainable infrastructure to advanced manufacturing and medical device development. This balanced approach, combining theoretical foundations with extensive practical experience, prepares engineers who can address immediate technical challenges while contributing to longer-term innovation initiatives.