Understanding Portable Laser Welding Machines in the United States

For individuals in the United States, portable laser welding machines present significant advantages in industrial and manufacturing settings. These machines are designed to enhance workflow by providing quick and efficient welding solutions. Their precision contributes to improved accuracy, reducing the likelihood of errors during the welding process. Additionally, these tools are instrumental in optimizing time use, allowing operators to complete tasks more efficiently. Various types of portable laser welding machines are available, each tailored for specific applications and use cases.

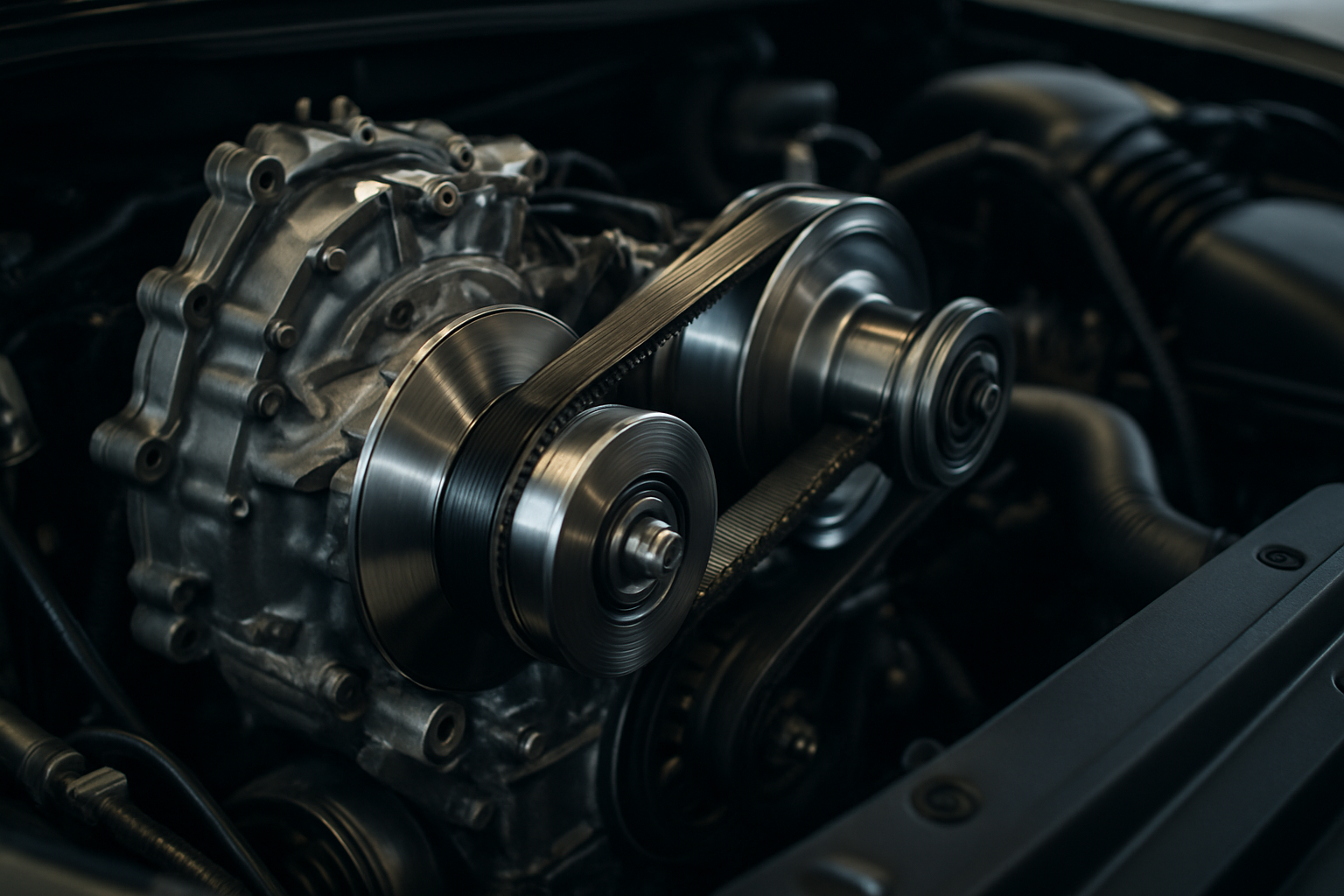

The welding industry in the United States has witnessed remarkable technological evolution over recent decades. Among the most notable innovations are portable laser welding machines, which combine the precision of laser technology with the convenience of mobility. These devices have become essential tools for professionals working in automotive repair, jewelry making, metal fabrication, and maintenance operations. Unlike traditional welding equipment that requires stationary setups and extensive infrastructure, portable laser welders offer flexibility and efficiency that align with modern workflow demands.

How Do Portable Laser Welding Machines Enhance Workflow Efficiency?

Portable laser welding machines significantly improve workflow efficiency by eliminating many constraints associated with conventional welding methods. These devices are lightweight and compact, allowing operators to bring the equipment directly to the workpiece rather than moving heavy materials to a fixed welding station. This mobility reduces setup time, minimizes material handling, and enables welding in confined spaces or on-site locations where traditional equipment would be impractical.

The efficiency gains extend beyond mobility. Portable laser welders typically feature quick startup times, often ready to operate within minutes of powering on. They require minimal consumables compared to traditional methods, reducing downtime for material replacement and lowering operational costs. The concentrated energy of the laser beam creates narrow heat-affected zones, which means less material distortion and fewer secondary finishing operations. For businesses managing multiple projects or working across different locations, the ability to transport welding capabilities easily translates directly into time savings and increased productivity.

Many modern portable laser welding systems include user-friendly interfaces with preset welding parameters for common materials and thicknesses. This feature streamlines the setup process, allowing operators to begin welding quickly without extensive manual adjustments. The combination of portability, speed, and reduced preparation time makes these machines particularly valuable in repair and maintenance scenarios where rapid response is essential.

What Makes Improving Accuracy in Welding Processes with Technology Possible?

Accuracy in welding has always been paramount for producing high-quality, reliable joints. Portable laser welding machines achieve exceptional precision through several technological features. The laser beam can be focused to extremely small spot sizes, often less than a millimeter in diameter, enabling welders to target specific areas with pinpoint accuracy. This precision is particularly valuable when working with thin materials, delicate components, or intricate designs where traditional welding methods might cause excessive heat damage or distortion.

Advanced portable laser welding systems incorporate real-time monitoring and feedback mechanisms. Some models feature integrated cameras or sensors that help operators visualize the weld pool and adjust parameters on the fly. The consistent energy delivery of laser technology produces uniform welds with repeatable quality, reducing variability that can occur with manual techniques. The minimal heat input and concentrated energy also mean that surrounding areas remain relatively unaffected, preserving the integrity of heat-sensitive components and reducing the risk of warping.

The digital control systems in modern portable laser welders allow for precise adjustment of power, pulse duration, and frequency. This level of control enables operators to optimize welding parameters for specific materials and joint configurations, achieving stronger, cleaner welds with minimal spatter or post-weld cleanup. For industries where precision is non-negotiable, such as aerospace components or medical device manufacturing, this technological accuracy provides a significant competitive advantage.

How Does Optimizing Time Use with Advanced Welding Solutions Benefit Operations?

Time optimization is a critical factor in manufacturing and repair operations, directly impacting profitability and customer satisfaction. Advanced portable laser welding solutions contribute to time savings throughout the entire welding process. The elimination of pre-heating requirements for many applications, combined with faster welding speeds compared to traditional methods, means projects can be completed more quickly without compromising quality.

The reduced need for post-weld processing represents another significant time advantage. Because laser welding produces clean, precise joints with minimal spatter and narrow heat-affected zones, finishing operations such as grinding, polishing, or paint preparation are often simplified or eliminated entirely. This streamlined workflow allows businesses to move products through production faster and reduces labor costs associated with secondary operations.

Portable laser welding machines also minimize downtime related to equipment maintenance and consumable replacement. Unlike traditional welding methods that require regular electrode changes, gas cylinder replacements, or nozzle cleaning, laser welders have fewer consumable components and longer maintenance intervals. The reliability and consistency of laser technology mean less time spent troubleshooting quality issues or reworking defective welds, further optimizing operational efficiency.

What Are the Cost Considerations for Portable Laser Welding Machines?

When evaluating portable laser welding machines, understanding the financial investment is essential for informed decision-making. The initial purchase price of these advanced systems varies considerably based on power output, features, and manufacturer. Entry-level portable laser welders suitable for small-scale operations or jewelry work typically start around $8,000 to $15,000. Mid-range industrial models with higher power outputs and additional features generally fall between $20,000 and $50,000. High-end systems designed for demanding industrial applications can exceed $70,000 or more.

Beyond the initial equipment cost, operators should consider ongoing expenses including maintenance, replacement parts, and consumables. While laser welders require fewer consumables than traditional methods, protective lenses, shielding gas, and occasional service requirements contribute to operational costs. Training expenses should also be factored in, as operators need proper instruction to maximize the technology’s benefits and ensure safe operation.

| Equipment Type | Power Range | Typical Cost Range | Best Suited For |

|---|---|---|---|

| Entry-Level Portable Laser Welder | 500W - 1000W | $8,000 - $15,000 | Jewelry, small repairs, thin materials |

| Mid-Range Industrial Model | 1000W - 1500W | $20,000 - $50,000 | General fabrication, automotive repair, maintenance |

| High-End Industrial System | 1500W - 2000W+ | $50,000 - $100,000+ | Heavy manufacturing, aerospace, demanding applications |

| Handheld Fiber Laser Welder | 1000W - 2000W | $15,000 - $45,000 | Versatile applications, on-site work, medium fabrication |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

What Applications Benefit Most from Portable Laser Welding Technology?

Portable laser welding machines excel in diverse applications across multiple industries. In automotive repair and restoration, these tools enable precise welding of body panels, exhaust systems, and structural components without the risk of warping or damaging adjacent parts. The portability allows technicians to work efficiently on vehicles without extensive disassembly. Jewelry manufacturers and repair specialists use portable laser welders for intricate work on precious metals, where precision and minimal heat impact are crucial.

Metal fabrication shops benefit from the versatility of portable laser welding when working with stainless steel, aluminum, titanium, and other materials. The technology is particularly valuable for joining dissimilar metals or working with thin-gauge materials that would be challenging with traditional methods. Maintenance and repair operations in industrial facilities, shipyards, and construction sites leverage the portability to perform on-site welding without transporting heavy equipment or materials.

The technology has also found applications in art and sculpture, where artists appreciate the precision and control for creating intricate metal works. Medical device manufacturing utilizes portable laser welding for producing small, precise components with biocompatible materials. As the technology becomes more accessible and affordable, new applications continue to emerge across industries seeking efficient, high-quality welding solutions.

Portable laser welding machines represent a significant advancement in welding technology, offering American professionals enhanced efficiency, precision, and flexibility. While the initial investment requires careful consideration, the operational benefits and time savings often justify the cost for businesses seeking to modernize their welding capabilities. As technology continues to evolve, these portable systems will likely become even more capable and accessible, further transforming how welding work is performed across the United States.