Welding Training in United States: A Path to Dynamic Careers

Welding training in United States offers individuals a chance to develop essential skills in a high-demand field. This training equips participants with the knowledge and practical abilities needed to excel in various industries. Engaging in welding training can lead to significant advancements in technical expertise and professional growth, fostering a robust foundation for future endeavors.

Welding stands as one of America’s cornerstone skilled trades, combining technical expertise with artistic precision to join metals through controlled fusion. Across the United States, welding training programs have evolved to meet the demands of modern industry while providing accessible career paths for those seeking hands-on, rewarding work. As manufacturing and infrastructure projects continue to drive economic growth, properly trained welders remain in consistent demand nationwide, making welding education a strategic investment in professional development.

Overview of Welding Training in United States

Welding education in the United States follows several established pathways, each offering distinct advantages depending on a student’s goals and circumstances. Community colleges typically provide two-year associate degree programs with comprehensive theoretical foundations alongside practical application. Technical and vocational schools offer concentrated certificate programs ranging from several months to a year, focusing primarily on hands-on skill development. Additionally, apprenticeship programs coordinated through unions or employer partnerships combine paid on-the-job training with classroom instruction over 3-5 years.

The American Welding Society (AWS) plays a crucial role in standardizing training across these diverse educational settings. Their certification programs ensure consistent quality and provide portable credentials recognized nationwide. Most reputable programs prepare students for AWS certification examinations, which serve as industry benchmarks for professional competence. Training facilities typically feature modern equipment including MIG, TIG, and stick welding stations, along with cutting tools, safety equipment, and increasingly, virtual reality simulators for preliminary practice.

Skills Developed Through Welding Training Programs

Technical welding proficiency forms the core of any training program, with students learning multiple welding processes including SMAW (stick), GMAW (MIG), GTAW (TIG), and FCAW (flux-cored). Each technique serves specific applications across industries, requiring distinct skill sets and equipment knowledge. Beyond the physical act of welding, students develop blueprint reading abilities, allowing them to interpret technical drawings and specifications critical to manufacturing and construction projects.

Material science knowledge constitutes another essential component, as welders must understand how different metals and alloys respond to heat, pressure, and various welding techniques. This includes recognizing potential complications like thermal distortion and implementing appropriate preventative measures. Safety protocols receive particular emphasis throughout training, covering proper ventilation, personal protective equipment usage, fire prevention, and electrical safety measures that protect both the welder and surrounding personnel.

Quality control and inspection skills round out the technical curriculum, teaching students to evaluate weld integrity through visual inspection and sometimes more advanced testing methods. Many programs also incorporate soft skills development, including communication, teamwork, and problem-solving abilities that enhance workplace effectiveness and career advancement opportunities.

Career Pathways Following Welding Training

Entry-level positions for newly certified welders typically include roles as welding technicians, fabricators, or production welders in manufacturing facilities. These positions provide valuable experience while allowing recent graduates to refine their skills in structured environments. With experience and additional certifications, career advancement opportunities expand considerably. Specialized welders working in underwater environments, pipeline construction, or aerospace applications often command premium salaries reflecting their advanced expertise and the challenging conditions they navigate.

Leadership roles represent another advancement pathway, with experienced welders moving into positions as welding supervisors, quality control inspectors, or shop foremen. These roles combine technical knowledge with management responsibilities, overseeing teams while ensuring adherence to quality standards and production timelines. For those with entrepreneurial aspirations, welding training provides the foundation for establishing independent businesses offering custom fabrication, repair services, or specialized welding solutions to commercial and residential clients.

The geographic mobility afforded by welding credentials represents a significant advantage in this career field. Certified welders can pursue opportunities nationwide, from shipyards along coastal regions to manufacturing centers throughout the Midwest or energy sector projects across multiple states. This flexibility allows professionals to follow industry demand or personal preferences when making career decisions.

Welding Training Program Options and Costs

Prospective welding students can choose from various program types depending on their career goals, budget, and time constraints. Community college programs typically cost between $5,000-$15,000 for state residents pursuing associate degrees, with higher rates for non-residents. Technical and vocational schools offer more concentrated certificate programs ranging from $3,000-$20,000 depending on program length and specialization level. Apprenticeship programs present a distinct advantage by providing paid on-the-job training, though competition for these positions can be significant.

| Program Type | Duration | Average Cost | Certification Opportunities |

|---|---|---|---|

| Community College | 1-2 years | $5,000-$15,000 | Associate degree, AWS certifications |

| Technical/Vocational School | 3-12 months | $3,000-$20,000 | Program certificate, AWS certifications |

| Apprenticeship | 3-5 years | Paid training | Journeyman status, AWS certifications |

| Manufacturer-Specific Training | 1-3 months | $1,000-$5,000 | Equipment-specific certifications |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Additional costs students should consider include welding equipment and safety gear (approximately $200-$800), certification examination fees ($250-$550 per test), and continuing education requirements for maintaining certifications. Many programs offer financial aid options including federal grants, scholarships through professional organizations like the American Welding Society, and employer tuition assistance programs for current workers seeking skill enhancement.

Industry Demand and Future Outlook

The welding profession continues to demonstrate strong demand across multiple sectors of the American economy. According to labor market analyses, skilled welders remain in consistent demand particularly in manufacturing, construction, aerospace, automotive, and energy production industries. This demand stems partially from demographic shifts as experienced welders reach retirement age, creating opportunities for new professionals entering the field.

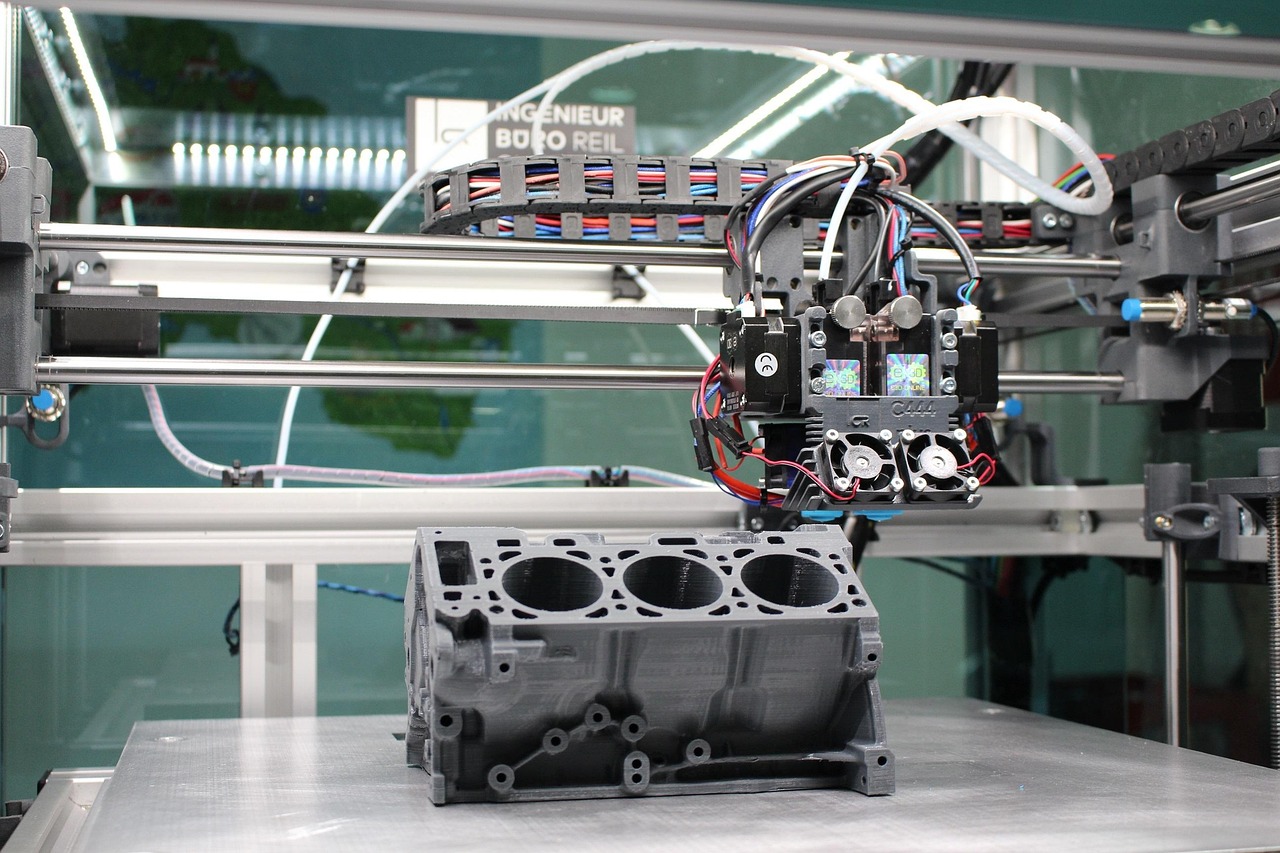

Technological advancements continue reshaping aspects of the welding profession, with automation and robotics handling certain repetitive tasks. However, these developments primarily change rather than eliminate welding careers, creating new roles focused on programming, maintaining, and supervising automated systems. Complex welding applications requiring judgment, adaptability, and specialized expertise remain firmly in the human domain, highlighting the continued relevance of comprehensive training programs.

The integration of advanced technologies into welding education itself represents another industry evolution, with virtual reality simulators allowing students to practice techniques before working with actual equipment. These innovations enhance safety while reducing material costs during the learning process, making training more efficient and accessible to diverse student populations across the United States.