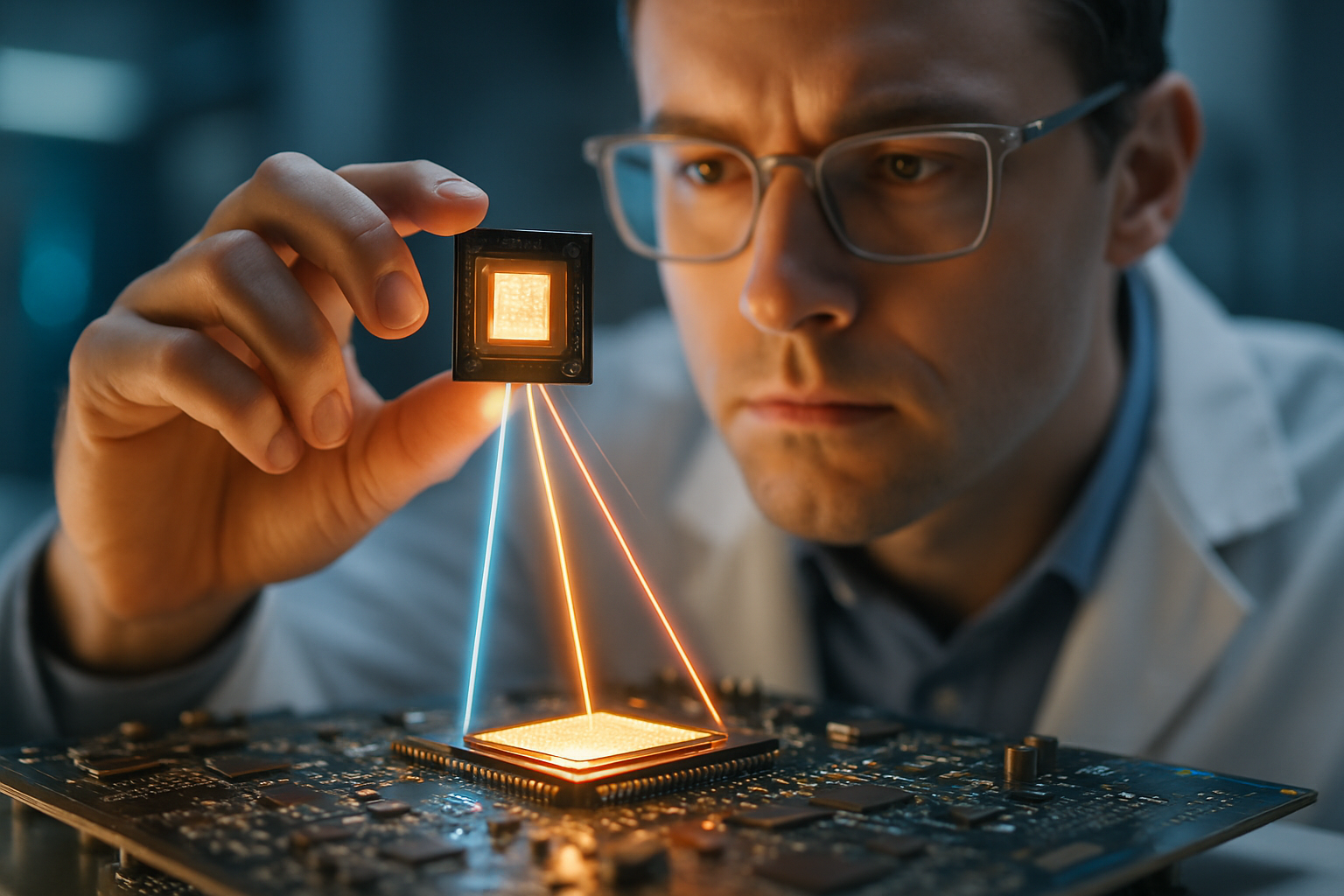

Liquid Metal: The Shape-Shifting Future of Electronics

In a world where rigid circuit boards and inflexible components dominate our devices, a revolutionary material is poised to transform the landscape of electronics. Liquid metal, once confined to the realm of science fiction, is now emerging as a game-changing technology with the potential to reshape how we design and interact with our gadgets. This shape-shifting substance promises to usher in an era of flexible, self-healing electronics that could revolutionize everything from smartphones to medical implants.

The concept of liquid metal in technology isn’t entirely new. Mercury, a toxic liquid metal, was once used in thermometers and electrical switches. However, the development of safer, non-toxic alternatives has reignited interest in liquid metal applications. Gallium-based alloys, in particular, have emerged as frontrunners due to their low toxicity and desirable physical properties.

Bending the Rules of Rigid Electronics

One of the most exciting aspects of liquid metal technology is its potential to create truly flexible electronics. Traditional circuit boards and wiring are inherently rigid, limiting the design possibilities for electronic devices. Liquid metal circuits, on the other hand, can be stretched, twisted, and bent without losing their electrical properties.

Researchers have already demonstrated prototypes of stretchable wires, antennas, and even entire circuit boards using liquid metal. These flexible components could pave the way for wearable devices that conform to the human body, foldable smartphones that don’t compromise on performance, and robust electronics for extreme environments.

Self-Healing Circuits: A Dream Come True

Perhaps one of the most intriguing properties of liquid metal is its ability to self-heal. When a liquid metal circuit is damaged or severed, the material can flow back together, restoring electrical connectivity. This self-healing capability could dramatically improve the longevity and reliability of electronic devices, potentially reducing electronic waste and the need for frequent replacements.

Imagine a smartphone that could repair its own circuitry after a drop, or a satellite that could mend damaged components in the harsh environment of space. These scenarios are becoming increasingly plausible as researchers refine liquid metal technologies.

From Lab to Market: Challenges and Opportunities

While the potential of liquid metal is enormous, several challenges must be overcome before it can become a mainstream technology. Controlling the flow and shape of liquid metal in complex circuits remains a significant hurdle. Additionally, ensuring long-term stability and preventing oxidation are crucial for practical applications.

Despite these challenges, several companies and research institutions are making significant strides in liquid metal technology. Start-ups like Liquid X Printed Metals and RMIT University’s Liquid Metal Research Centre are at the forefront of developing commercial applications. These range from printed electronics for smart packaging to advanced thermal management systems for electronics.

The market potential for liquid metal technologies is substantial, with estimates suggesting it could reach several billion dollars within the next decade. As manufacturing processes improve and new applications emerge, the cost of liquid metal components is expected to decrease, making them more accessible for consumer electronics and industrial applications.

A Glimpse into the Liquid Future

As liquid metal technology continues to evolve, we can expect to see a wide range of innovative applications. Soft robotics could benefit from liquid metal actuators that mimic natural movements. Medical devices could incorporate liquid metal electrodes for better bio-compatibility and adaptability to the human body. Even the burgeoning field of neuromorphic computing could leverage liquid metal’s unique properties to create more efficient, brain-like circuits.

The integration of liquid metal with other emerging technologies, such as 3D printing and nanotech, promises to unlock even more possibilities. Researchers are exploring ways to 3D print complex liquid metal structures, potentially revolutionizing how we manufacture electronic components.

In conclusion, liquid metal represents a paradigm shift in electronics, offering a future where our devices are no longer constrained by rigid materials. As this technology matures, we can look forward to a new generation of electronics that are more flexible, resilient, and adaptable than ever before. The fluid nature of liquid metal may very well be the key to unlocking the next wave of technological innovation, reshaping our relationship with electronics in ways we’re only beginning to imagine.